When it comes to achieving reliable and long-lasting seals in aggressive chemical environments, few materials perform as well as PTFE (Polytetrafluoroethylene). Known for its exceptional chemical inertness, non-stick surface, and wide temperature tolerance, PTFE has become a preferred choice for gasket manufacturing worldwide.

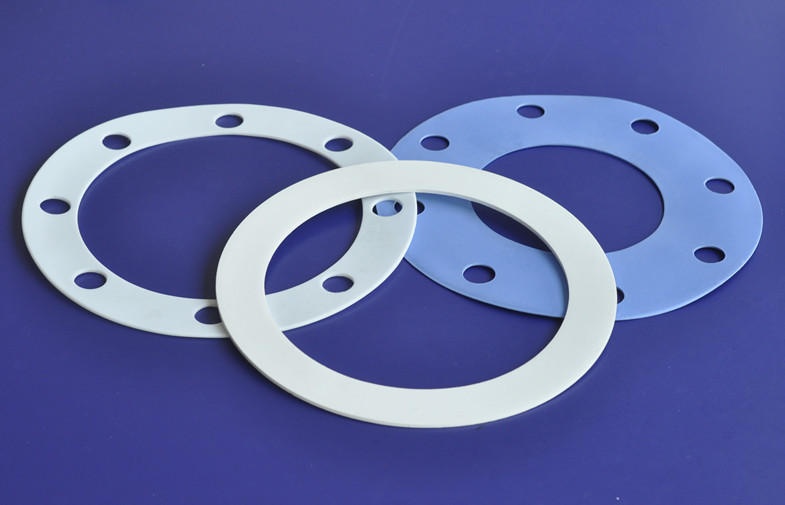

As a leading PTFE gasket supplier, we specialize in providing durable and high-precision sealing solutions that perform under pressure. Whether it’s for chemical plants, food industries, or high-temperature systems, our PTFE gaskets deliver superior sealing integrity and resistance where it matters most.

What is a PTFE Gasket?

A PTFE gasket is a type of sealing element crafted from polytetrafluoroethylene—a synthetic fluoropolymer commonly recognized under the trade name Teflon. It serves as a barrier between two mating surfaces, preventing leakage of gases or liquids.

What makes PTFE unique is its inertness—it doesn’t react with most chemicals, even under harsh conditions. It also maintains dimensional stability at both cryogenic and high temperatures. This makes PTFE gaskets suitable for critical applications in chemical, pharmaceutical, and food industries where safety and purity are paramount.

Advantages of PTFE Gaskets

PTFE gaskets are designed to outperform traditional materials like rubber, graphite, or fiber-based seals. Here are the main benefits that make PTFE the material of choice:

1. Exceptional Chemical Resistance

PTFE is virtually resistant to all chemicals, acids, and bases except for molten alkali metals and elemental fluorine. This allows PTFE gaskets to handle corrosive and reactive fluids with ease.

2. Wide Temperature Range

PTFE gaskets can operate between -200°C and +260°C, making them ideal for both cryogenic and high-temperature sealing applications.

3. Non-Stick Surface

PTFE’s smooth surface prevents sticking and accumulation of process media, ensuring clean operations in sanitary industries like pharmaceuticals and food processing.

4. Excellent Electrical Insulation

The high dielectric strength of PTFE makes it perfect for electrical and electronic sealing applications.

5. Low Friction and High Wear Resistance

With an ultra-low friction coefficient, PTFE gaskets minimize surface wear, extending service life even in dynamic sealing conditions.

6. Non-Toxic and Food-Safe

PTFE gaskets comply with FDA, USP Class VI, and 3-A Sanitary Standards, ensuring suitability for applications requiring purity and hygiene.

7. Weather and UV Resistance

PTFE does not degrade under sunlight or exposure to moisture, making it an excellent option for outdoor and marine environments.

Types of PTFE Gaskets

To serve different operational needs, PTFE gaskets are available in several variants. Below are the most widely used types:

1. Virgin PTFE Gaskets

These are made from 100% pure PTFE resin without fillers. They are ideal for high-purity applications where contamination must be avoided, such as in pharmaceuticals and food processing.

2. Filled PTFE Gaskets

Filled PTFE combines PTFE resin with additives like glass, carbon, graphite, or bronze to improve specific properties:

- Glass-filled PTFE – enhances compressive strength and dimensional stability.

- Graphite-filled PTFE – improves heat dissipation and reduces thermal expansion.

- Carbon-filled PTFE – increases wear resistance and hardness.

- Bronze-filled PTFE – provides improved mechanical strength and creep resistance.

3. Expanded PTFE (ePTFE) Gaskets

Expanded PTFE is a soft, flexible form of PTFE that easily conforms to flange imperfections. It provides superior sealing performance even under low bolt loads.

4. Envelope PTFE Gaskets

These gaskets have a PTFE outer layer enclosing a soft core material (like rubber or fiber). They combine the elasticity of the core with PTFE’s chemical resistance.

5. Skived PTFE Gaskets

Produced from precision-skived sheets, these gaskets are used where accurate dimensions and tight tolerances are required.

Applications of PTFE Gaskets

Because of their superior properties, PTFE gaskets find applications across a wide range of industries and systems:

1. Chemical Processing Plants

Used in flanges, reactors, and pipe joints handling acids, alkalis, and solvents.

2. Petrochemical and Refinery Units

Ideal for sealing pipelines, valves, and heat exchangers that encounter hydrocarbons and corrosive gases.

3. Pharmaceutical Manufacturing

Ensures sterile and contamination-free sealing in cleanrooms, reactors, and bioprocessing systems.

4. Food and Beverage Processing

Used in bottling lines, dairy plants, and food packaging equipment where hygiene is critical.

5. Power Generation

Provides leak-free sealing in steam, fuel, and water lines operating under high pressure and temperature.

6. Water Treatment Facilities

Seals components in filtration systems, desalination units, and chemical dosing equipment.

7. Aerospace and Electronics

Used in sensitive systems that demand precision sealing and high electrical insulation.

PTFE Gasket Manufacturing Process

Producing high-quality PTFE gaskets requires a combination of advanced materials, modern technology, and stringent quality checks. Here’s how we manufacture them:

- Material Selection

High-grade PTFE or filled PTFE resin is selected based on the end-use requirement. - Molding and Sintering

The resin is molded into billets and sintered under controlled heat to achieve the desired density and mechanical strength. - Skiving or Machining

Sheets or rings are skived from billets with precise thickness, ensuring uniformity. - Cutting and Shaping

Gaskets are cut using die-cutting, water jet, or CNC machining for precision and dimensional accuracy. - Inspection and Testing

Every gasket undergoes rigorous quality checks for surface finish, tolerance, and leak performance. - Packaging and Dispatch

Finished products are carefully packed to prevent damage and contamination during storage and transport.

Why Choose Us as Your PTFE Gasket Supplier

Selecting the right PTFE gasket supplier ensures your operations remain efficient, safe, and compliant. Here’s why we’re trusted by clients worldwide:

1. Quality You Can Trust

We manufacture PTFE gaskets that meet or exceed international standards like ASTM, DIN, and ASME.

2. Customization for Every Application

We provide tailor-made gaskets in different dimensions, shapes, and filler compositions to meet your precise needs.

3. Consistent Performance

Our gaskets maintain their integrity under extreme pressure and temperature fluctuations.

4. Affordable and Reliable

We balance quality with cost-effectiveness, offering the best value for industrial sealing solutions.

5. Expert Support

Our experienced engineers assist with material selection, design recommendations, and installation guidance.

6. Global Reach

With a strong supply chain and distribution network, we serve clients across domestic and international markets.

Industries We Serve

Our PTFE gaskets are trusted across a variety of industries, including:

- Oil and Gas

- Petrochemical

- Food & Beverage

- Pharmaceutical

- Power Generation

- Pulp & Paper

- Marine & Offshore

- Water Treatment

We design our products to withstand demanding conditions, ensuring safety and reliability in every application.

Quality and Certifications

We maintain strict quality standards throughout the manufacturing process. Our PTFE gaskets comply with:

- ISO 9001:2015 Quality Management Systems

- FDA & USP Class VI Certifications

- ASTM F104 Material Standards

- RoHS & REACH Compliance

Every gasket is inspected for dimensional accuracy, tensile strength, and thermal stability before delivery.

Commitment to Sustainability

We take pride in eco-friendly manufacturing practices. Our PTFE gaskets are asbestos-free, non-toxic, and recyclable. By optimizing energy use and reducing material waste, we support a sustainable and responsible production process.

Conclusion

PTFE gaskets have redefined industrial sealing with their outstanding chemical resistance, high-temperature performance, and long service life. Whether used in chemical plants, food facilities, or high-pressure pipelines, they ensure safety and operational efficiency.