Medical scales are more than just devices for measuring weight-they are critical tools in healthcare settings, influencing diagnoses, treatment plans, and patient monitoring. But the accuracy and reliability of these scales depend heavily on their accessories and how well they are maintained and calibrated. Neglecting these aspects can lead to incorrect readings, which might compromise patient care.

Why Calibration Matters for Medical Scale Accessories

Calibration ensures that a medical scale and its accessories provide precise and consistent measurements. Accessories such as height rods, wheelchair attachments, and baby weighing trays must be calibrated alongside the main scale to maintain overall accuracy. The importance of calibration cannot be overstated, as it forms the backbone of reliable patient care in any medical setting. Inaccurate measurements can lead to misdiagnoses, inappropriate treatment plans, and ultimately, compromised patient safety.

Imagine a pediatric clinic where an infant’s weight is measured using a baby tray attachment. If the tray isn’t correctly calibrated, the reading could be off by several ounces or even pounds, leading to improper medication dosages or misjudged growth patterns. This isn’t just inconvenient—it can be dangerous. For instance, a slight underestimation of an infant’s weight could result in a healthcare provider administering too little medication, while an overestimation could lead to an overdose. In both scenarios, the stakes are high, highlighting the critical role of accurate measurements in pediatric healthcare.

Calibration is not a one-time task. Over time, wear and tear, environmental changes, and frequent use can cause drift in measurement accuracy. Regular calibration checks catch these deviations early, ensuring that every reading is trustworthy. Moreover, factors such as humidity, temperature fluctuations, and even the physical handling of the scale can impact its performance. Therefore, understanding the specific conditions under which the medical scales operate is essential for maintaining their accuracy over time.

How Calibration Works

Calibration typically involves comparing the scale’s readings against known standards or certified weights. For accessories, this might mean verifying that a height rod measures correctly or that a wheelchair platform accurately supports and weighs a patient without distortion. The process often includes adjusting the scale’s settings to align with these standards, ensuring that every component functions harmoniously. Technicians may also perform functional tests to confirm that the scale responds accurately to different weights and that all accessories are integrated seamlessly into the measurement process.

Certified calibration weights are essential. These weights have been tested and certified by national or international standards organizations, providing a reliable benchmark. Using uncertified weights or makeshift objects can introduce errors rather than eliminate them. The integrity of the calibration process hinges on these certified weights, as they serve as the gold standard against which all measurements are evaluated. Additionally, the traceability of these weights to recognized standards adds an extra layer of credibility to the calibration process, ensuring compliance with regulatory requirements in healthcare settings. For professional calibration services and high-quality scales, you can visit Scales 4 U.

When to Calibrate Medical Scale Accessories

Calibration should be performed:

- Upon initial installation of the scale and accessories

- After any repair or replacement of parts

- Periodically, according to manufacturer recommendations or regulatory guidelines

- Whenever the scale is moved to a new location

- When readings seem inconsistent or questionable

Routine calibration schedules vary but commonly occur every six months to a year. Some high-usage environments might require more frequent checks. For example, in busy hospital wards or outpatient clinics where scales are used continuously, a quarterly calibration schedule may be necessary to ensure ongoing accuracy. Furthermore, keeping meticulous records of calibration dates and results can help healthcare facilities maintain compliance with industry standards and provide a clear audit trail for inspections.

In addition to routine checks, staff training on the importance of calibration is crucial. Ensuring that all personnel understand how to operate the scales correctly and recognize signs of potential inaccuracies can prevent issues before they arise. Regular training sessions can reinforce the significance of calibration and empower staff to take ownership of the equipment they use daily, ultimately leading to better patient outcomes and enhanced operational efficiency.

Common Medical Scale Accessories and Their Maintenance Needs

Medical scales come with a variety of accessories tailored to different patient needs. Each accessory has unique maintenance requirements to ensure longevity and accuracy.

Height Rods

Height rods are used to measure patient height alongside weight. They must be checked for alignment and calibration regularly. A crooked or loose height rod can give inaccurate measurements.

Maintenance tips include:

- Cleaning the rod and measurement markings to ensure visibility

- Checking the locking mechanisms to prevent movement during measurement

- Verifying the zero point at the base to ensure measurements start accurately

Wheelchair Platforms

Wheelchair scales allow patients who cannot stand to be weighed accurately. These platforms must be sturdy and level, with sensors calibrated to handle the combined weight of the wheelchair and patient.

Maintenance involves:

- Inspecting for structural damage or wear

- Ensuring the platform surface is clean and free of debris

- Calibrating sensors regularly to maintain accuracy

- Checking ramps and safety rails for stability

Baby Weighing Trays

Infant trays are designed to safely hold babies during weighing. Because infants are sensitive and measurements must be exact, these trays require careful calibration and maintenance.

Key maintenance steps include:

- Cleaning with non-toxic, gentle disinfectants

- Inspecting for cracks or sharp edges

- Calibrating the scale with the tray in place to account for its weight

Step-by-Step Guide to Calibrating Medical Scale Accessories

Calibration can seem daunting, but breaking it down into clear steps makes it manageable.

1. Prepare the Scale and Accessories

Start by ensuring the scale and accessories are clean and free from obstructions. Remove any dust, dirt, or residue that could interfere with measurements. Place the scale on a flat, stable surface and ensure it is level.

2. Warm Up the Scale

Turn on the scale and let it warm up for at least 15 minutes. This allows the internal components to stabilize, providing more consistent readings.

3. Check the Zero Point

With the scale empty and accessories attached, verify that the display reads zero. If not, use the tare or zero function to reset it. This step is crucial for accessories like baby trays or wheelchair platforms, where the accessory’s weight must be accounted for.

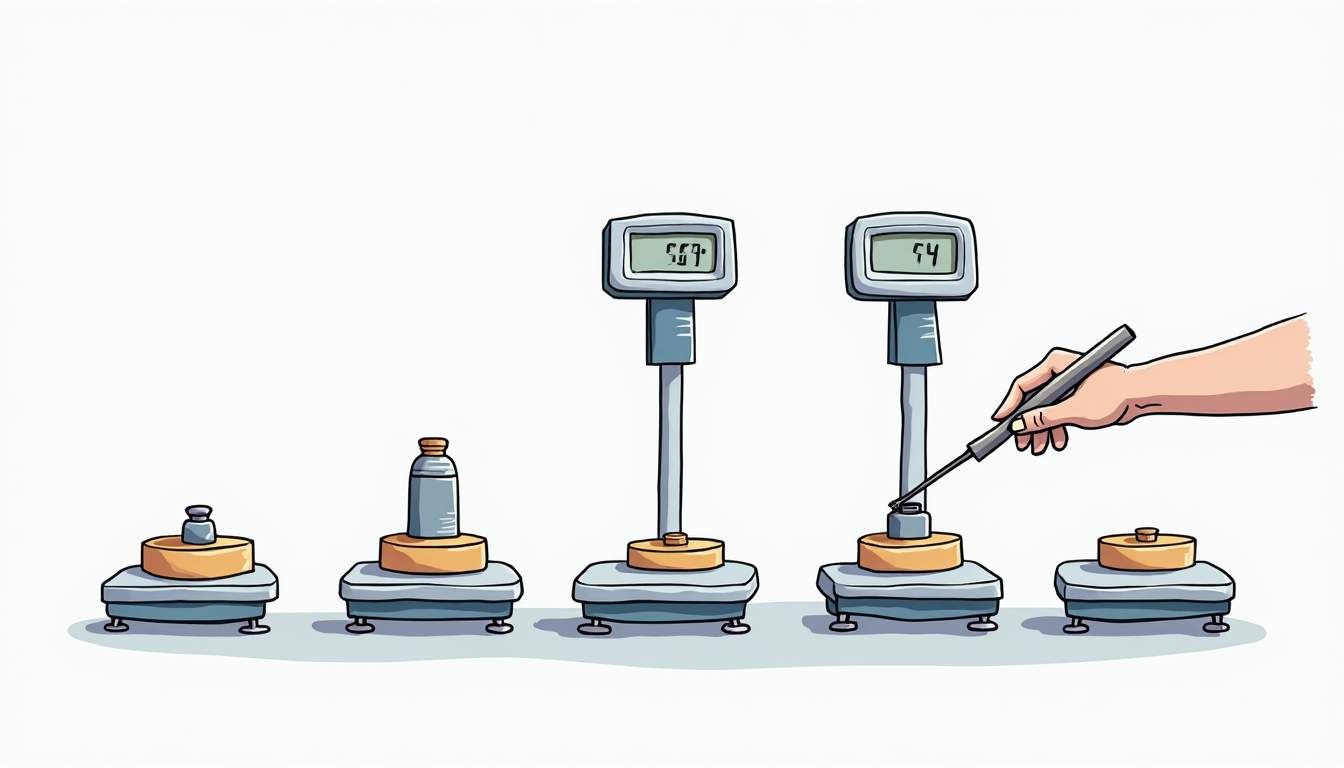

4. Use Certified Calibration Weights

Place certified weights on the scale, noting the displayed value. For accessories like height rods, use a measuring tape or certified height standard to verify accuracy. Record any discrepancies.

5. Adjust the Scale

If the readings deviate beyond acceptable limits, adjust the scale according to the manufacturer’s instructions. This may involve using calibration screws, software interfaces, or calibration modes.

6. Repeat and Confirm

After adjustments, repeat the weighing or measuring process to confirm accuracy. Perform multiple tests to ensure consistency.

7. Document the Calibration

Keep detailed records of calibration dates, results, adjustments made, and the person responsible. Documentation supports compliance with healthcare regulations and quality assurance.

Routine Maintenance Practices to Extend Accessory Lifespan

Regular maintenance not only preserves accuracy but also extends the life of medical scale accessories.

Cleaning and Disinfection

Medical environments demand strict hygiene. Clean accessories after each use with appropriate disinfectants that won’t damage materials. Avoid harsh chemicals that can erode surfaces or fade measurement markings.

Physical Inspections

Inspect accessories for signs of wear, corrosion, or damage. Look for loose screws, cracks, or worn-out components. Address issues promptly to prevent further damage or inaccurate readings.

Environmental Considerations

Keep scales and accessories in controlled environments. Excessive humidity, temperature fluctuations, or exposure to direct sunlight can affect calibration and durability. Store calibration weights in protective cases when not in use.

Training Staff

Ensure all personnel who use or maintain medical scales understand proper handling and calibration procedures. Improper use can cause damage or inaccurate readings. Regular training updates help maintain standards.

Common Challenges and How to Overcome Them

Even with best practices, challenges arise. Understanding common issues helps in troubleshooting effectively.

Drift in Calibration

Calibration drift occurs when readings gradually become inaccurate over time. Causes include mechanical wear, sensor fatigue, or environmental factors. Regular calibration schedules and environmental controls reduce drift.

Inconsistent Readings

Fluctuating measurements can result from unstable surfaces, electrical interference, or damaged accessories. Always use scales on flat, stable surfaces and check for nearby equipment that might cause interference.

Accessory Compatibility

Using non-compatible accessories can cause errors. Always verify that accessories are designed for the specific scale model. Manufacturer guidelines provide compatibility information.

Documentation Gaps

Failing to document calibration and maintenance can lead to compliance issues and difficulty tracking performance. Implement standardized logs and digital records to maintain thorough documentation.

Regulatory and Quality Standards

Healthcare facilities must comply with regulatory standards for medical equipment, including scales and their accessories. Organizations such as the FDA and ISO provide guidelines for calibration and maintenance.

Adhering to these standards ensures patient safety and helps avoid legal and accreditation problems. Regular audits often review calibration records and maintenance logs.

ISO 13485 and Medical Scales

ISO 13485 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and regulatory requirements. Calibration and maintenance of medical scales fall under this umbrella.

FDA Regulations

The FDA regulates medical devices, including scales used in clinical settings. Proper calibration and maintenance are part of the device’s performance requirements. Non-compliance can lead to recalls or penalties.

Final Thoughts

Medical scale accessories might seem like minor components, but their calibration and maintenance are vital for accurate patient assessments. Investing time and resources into proper calibration routines, regular maintenance, and staff training pays off in reliable measurements and improved patient outcomes.

Ignoring these responsibilities risks inaccurate data, compromised treatments, and potential safety hazards. Make calibration and maintenance a priority-because every ounce and inch counts in healthcare.