Polyethylene terephthalate (PET) flakes are a cornerstone of the recycling industry, widely used in producing fibers, sheets, bottles, and other sustainable products. As demand for recycled materials grows, choosing the right PET flakes manufacturer becomes critical for businesses that rely on consistent quality and ecofriendly practices. With numerous suppliers already existing in the market, it’s essential to know which qualities set the best manufacturers apart.

Understanding PET Flakes

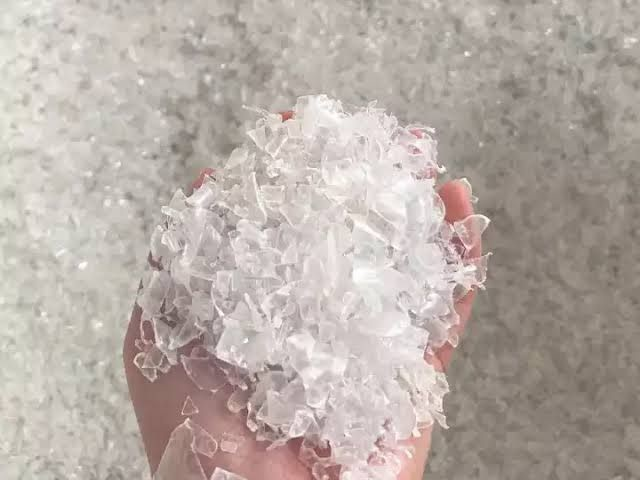

PET flakes are produced by recycling used PET bottles and containers. The process involves collection, cleaning, shredding, and sorting to create flakes that can be reused in various industries. These flakes are valued for their durability, versatility, and contribution to reducing plastic waste.

A reliable PET flakes manufacturer ensures that the recycling process meets international standards, producing flakes that are safe, clean, and suitable for further processing.

Key Qualities to Look for in a Pet Flakes Manufacturer

- Quality Assurance : The foremost quality of a good manufacturer is their commitment to producing highgrade PET flakes. Look for suppliers who adhere to the strict quality control measures, ensuring flakes are free from contaminants such as PVC, metals, or paper. Consistency in color, size, and purity is vital for industries like textiles and packaging.

- Advanced Technology : Modern recycling requires advanced machinery for washing, drying, and sorting PET materials. A reputable PET flakes manufacturer invests in stateoftheart equipment to deliver superior products. Automated systems minimize the human error and enhance efficiency, resulting in cleaner and more uniform flakes.

- Environmental Responsibility: Sustainability is at the heart of PET recycling. Choose manufacturers who prioritize ecofriendly practices, such as water recycling, energyefficient processes, and minimal waste generation. Certifications like ISO 14001 or compliance with local environmental regulations indicate a strong commitment to green manufacturing.

- Supply Chain Reliability: Timely delivery and consistent supply are crucial for businesses that depend on PET flakes. A dependable manufacturer maintains robust logistics and inventory management systems to meet client demands without delays. Reliability in supply ensures smooth production cycles for downstream industries.

- Transparency and Certifications : Trustworthy manufacturers provide detailed documentation about their processes, product specifications, and certifications. Look for suppliers with recognized accreditations such as FDA approval (for foodgrade PET flakes) or GRS (Global Recycling Standard). Transparency builds confidence and longterm partnerships.

- Customization Options: Different industries require PET flakes with specific properties. A versatile PET Flakes Manufacturer offers customization in terms of flake size, color, and grade. This flexibility allows businesses to source materials tailored to their unique applications, whether for textiles, packaging, or construction.

- Global Standards Compliance: International trade often requires compliance with global standards. Manufacturers who meet EU, US, or Asian market requirements ensure their products can be exported and used worldwide. This is especially important for companies operating across borders.

- Customer Support: Strong customer service is a hallmark of a reliable manufacturer. From technical assistance to aftersales support, responsive communication helps resolve issues quickly and fosters longterm collaboration. A manufacturer that values customer relationships will go the extra mile to meet expectations.

- Competitive Pricing : While quality should never be compromised, cost efficiency matters. The best manufacturers balance affordability with high standards, offering competitive pricing without cutting corners. Transparent pricing models help businesses plan budgets effectively.

- Reputation and Experience: Experience in the recycling industry is a strong indicator of reliability. Established manufacturers with a proven track record are more likely to deliver consistent quality and maintain ethical practices. Checking reviews, testimonials, and industry references can help assess reputation.

Why Choosing the Right Pet Flakes Manufacturer Matters?

Selecting the right manufacturer impacts not only product quality but also brand reputation and sustainability goals. Poorquality flakes can lead to production issues, increased costs, and compromised end products. On the other hand, partnering with a trusted PET Flakes Manufacturer ensures smooth operations, ecofriendly practices, and customer satisfaction.

Applications of PET Flakes

PET flakes are used across diverse industries, including:

- Textiles: For polyester fibers and fabrics.

- Packaging: In manufacturing bottles, containers, and films.

- Construction: As raw material for sheets and insulation products.

- Automotive: In producing durable plastic components.

- Consumer goods: From carpets to household items.

The versatility of PET flakes makes them indispensable, and the quality of the manufacturer directly influences the performance of these products.

Conclusion

Finding the right PET Flakes Manufacturer requires careful evaluation of their quality standards, technology, sustainability practices, and customer service. By prioritizing these qualities, businesses can secure a reliable supply of highgrade PET flakes that support both production efficiency and environmental responsibility.

In a world increasingly focused on sustainability, choosing a manufacturer who aligns with your values and operational needs is not just a business decision it’s a commitment to a greener future.