Mechanical design has changed a lot in recent years, thanks to improvements in 3D modeling technology. Mechanical 3D Modeling Services have grown from basic design tools to complete solutions that can simulate complex machines with high accuracy. Today, industries like automotive, aerospace, and consumer products rely heavily on these services. Using 3D models, companies can spot mistakes early, save costs, and bring products to market faster.

The need for fast, high-quality, and customized products has pushed engineers to use the latest trends in mechanical 3D modeling. Modern Mechanical 3D Modeling Services go beyond simple CAD drawings. They now use cloud computing, artificial intelligence (AI), virtual reality (VR), and advanced simulations. These tools help engineers test different designs, predict real-world performance, and work together smoothly across teams, even in different locations. Companies that use these services can stay ahead of the competition while delivering better products to their customers.

How AI is Changing 3D Modeling

AI and machine learning are now a big part of Mechanical 3D Modeling Services. In the past, engineers had to manually design every part of a product, which took a lot of time and effort. AI tools can now study existing design data and suggest the best shapes, materials, and layouts for a project. This helps engineers save time and create more accurate designs.

Machine learning can also predict where parts might fail before the product is even made. By analyzing past designs and test results, AI can point out weak spots and suggest improvements. This is especially helpful in industries like aerospace and automotive, where safety is crucial. With AI, mechanical 3D modeling becomes faster, more accurate, and more reliable.

Cloud-Based 3D Modeling

Cloud technology is another trend changing Mechanical 3D Modeling Services. Cloud platforms let engineers work on 3D models from anywhere. Teams in different cities or countries can collaborate in real-time. Unlike traditional software, which often needs a high-powered computer, cloud services offer strong computing and storage online. This makes it easy to handle large, complex models without slowing down.

Cloud platforms also connect easily with other tools, like product lifecycle management (PLM) software and simulation programs. Engineers can share files, track changes, and keep everything organized. Using cloud-based 3D modeling helps teams work faster, reduce mistakes, and get projects done on time.

Generative Design for Smarter Products

Generative design is a big trend in Mechanical 3D Modeling Services. It uses AI to create hundreds or even thousands of design options based on specific goals, like strength, weight, or cost. Engineers can then choose the best option for production.

This is very useful in industries like aerospace and automotive, where products need to be strong but lightweight. Generative design helps reduce material use, cut costs, and improve performance. It also allows engineers to try new ideas and create shapes that would be impossible with traditional methods.

Virtual Reality and Augmented Reality

VR and AR are becoming more common in Mechanical 3D Modeling Services. VR lets engineers explore 3D models in a fully digital space, where they can zoom in, rotate, and inspect parts closely. This makes it easier to find problems early in the design process.

AR overlays digital models onto the real world. For example, engineers can see how a mechanical component will fit in a factory before it’s built. Using VR and AR helps teams work better together, reduces errors, and speeds up product development.

Focusing on Sustainability

Sustainability is an important trend in modern Mechanical 3D Modeling Services. Engineers now aim to design products that are efficient and environmentally friendly. Many 3D modeling tools can simulate the environmental impact of different materials and manufacturing methods. This helps companies make better decisions and reduce waste.

Additive manufacturing (3D printing) is also used to create prototypes and parts with minimal material waste. By focusing on sustainability, businesses can meet regulations, attract eco-conscious customers, and reduce their impact on the environment.

Simulation and Analysis Tools

Simulation is a key part of Mechanical 3D Modeling Services. Engineers can test parts under stress, heat, vibration, and fluid flow to see how they will perform in real life. This reduces the need for physical prototypes, saving time and money.

Tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are widely used. FEA checks the strength of materials, while CFD examines airflow or fluid movement around parts. These simulations help engineers improve designs and make products more reliable.

Custom Designs for Clients

Clients today want products designed specifically for their needs. Mechanical 3D Modeling Services now offer flexible, client-focused solutions. Parametric modeling lets engineers quickly change dimensions, materials, or configurations without starting over.

Many services also provide detailed instructions for assembly and manufacturing, making it easier to produce custom designs. This approach increases client satisfaction and strengthens business relationships.

Cross-Industry Collaboration

Mechanical 3D modeling is no longer limited to traditional engineering sectors. Fields like healthcare, electronics, and construction are using these services more often. Medical companies use 3D models for surgical tools and implants, while construction firms design mechanical systems for buildings.

Standard file formats and software compatibility make it easy for engineers from different industries to share models, give feedback, and improve designs together. This collaboration helps companies innovate faster and produce better products.

Robotics and Automation

Automation and robotics are enhancing Mechanical 3D Modeling Services further. Engineers can simulate how robots will work with mechanical components on assembly lines. This helps identify problems, improve workflows, and save time.

Automation also speeds up repetitive tasks in design, allowing engineers to focus on complex problems. Combining robotics with 3D modeling leads to more efficient production systems and better products.

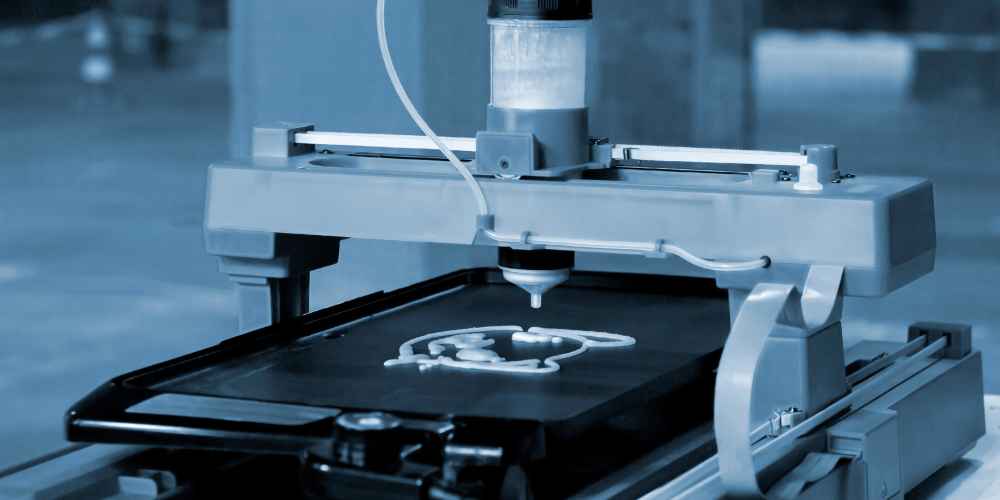

Additive Manufacturing (3D Printing)

3D printing is closely linked to mechanical 3D modeling. Engineers can turn 3D models into real parts, including complex shapes that traditional manufacturing cannot create. This speeds up testing and design improvements.

Additive manufacturing also supports on-demand production. Companies can make parts when needed, reducing inventory and reacting quickly to market changes. Together, 3D modeling and 3D printing open up new possibilities for innovation, customization, and efficiency.

Looking Ahead

The future of Mechanical 3D Modeling Services is bright. New technologies like digital twins, Internet of Things (IoT) integration, and AI-driven generative design will make 3D modeling even more powerful. Digital twins create virtual versions of real products, allowing engineers to monitor performance, prevent problems, and optimize designs in real-time.

As these tools become more advanced, mechanical 3D modeling will remain essential for designing, testing, and manufacturing products. Companies that adopt the latest trends will stay competitive, cut costs, and deliver better products to customers.

Conclusion

Mechanical 3D Modeling Services have grown from simple CAD drawings to advanced solutions with AI, cloud computing, VR/AR, and simulation. These trends help engineers design faster, reduce mistakes, and make higher-quality products.

Sustainability, customization, and cross-industry applications show how versatile these services have become. Businesses that embrace modern 3D modeling trends will gain a competitive edge, improve efficiency, and meet customer expectations. As technology continues to evolve, mechanical 3D modeling will remain a key part of innovation in engineering and manufacturing.