For many businesses, the product label is more than just an identifier — it’s a statement of quality. Whether it’s a food jar, cosmetic container, or an industrial part, the label tells customers who you are and what you stand for. But in harsh conditions, labels can fade, peel, or disintegrate, compromising not just the look but your brand’s credibility. That’s where weatherproof labels step in.

These specialized labels are engineered to endure moisture, heat, cold, and chemicals — ensuring that your brand remains intact even when your products face tough environments. From frozen storage to outdoor exposure, weatherproof labeling protects your investment and keeps your business looking professional, no matter where your products go.

Why Label Durability Equals Brand Trust

Customers rarely think about labels until they see one fail. A peeling or water-damaged label instantly signals poor quality, even if the product itself is perfect. In a competitive marketplace, such small visual cues can sway buying decisions.

Durability in labeling is, therefore, not just a technical issue but a branding one. Whether your products are sold on store shelves, shipped across the country, or used outdoors, your label has to withstand the same conditions as your product. If it can’t, your reputation may take a hit long before the product itself fails.

That’s why brands across industries — from beverages to construction materials — are shifting toward durable, weatherproof vinyl label materials that can resist water, sunlight, and abrasion.

Understanding What Makes a Label “Weatherproof”

Weatherproof labels are not just waterproof — they’re designed to handle the full spectrum of environmental stressors. This includes UV rays, humidity, chemical exposure, and temperature swings. Achieving that resilience involves several key elements:

- Material Composition: Most weatherproof labels use vinyl or polyester substrates rather than paper. Vinyl, in particular, offers flexibility and resistance to tearing.

- Adhesive Strength: High-performance adhesives keep labels attached even on textured or curved surfaces, whether dry, wet, or oily.

- Protective Coating: A glossy or matte laminate protects printed information from fading, scratching, or smudging.

- Ink Compatibility: Labels printed with resin-based ribbons or pigment inks are far more durable than those using dye inks.

Together, these features ensure that your labels remain legible and attractive across varied use cases — from refrigerated goods to industrial equipment.

The Real Cost of Poor Label Performance

Small businesses sometimes choose standard paper labels to save costs, assuming all labels are created equal. But the hidden cost of a label failure can be enormous.

Imagine a candle jar with a wrinkled label from heat exposure, or a cleaning product whose label smudges when wet — the product looks cheap, the brand looks careless, and the customer moves on.

Beyond aesthetics, unreadable barcodes or safety instructions can create logistical or compliance issues. For industrial products, missing warning symbols or fading serial codes could even lead to liability concerns.

Weatherproof labeling mitigates all these risks. It ensures that your labels — and by extension, your brand — perform consistently, regardless of what conditions your products face.

Choosing the Right Material for the Job

Selecting the right weatherproof label involves matching material properties to your environment and product type.

Vinyl Labels: Flexible and Long-Lasting

Vinyl labels are the most versatile option, offering superior flexibility and durability. They adhere well to curved or uneven surfaces and resist moisture, UV light, and abrasion.

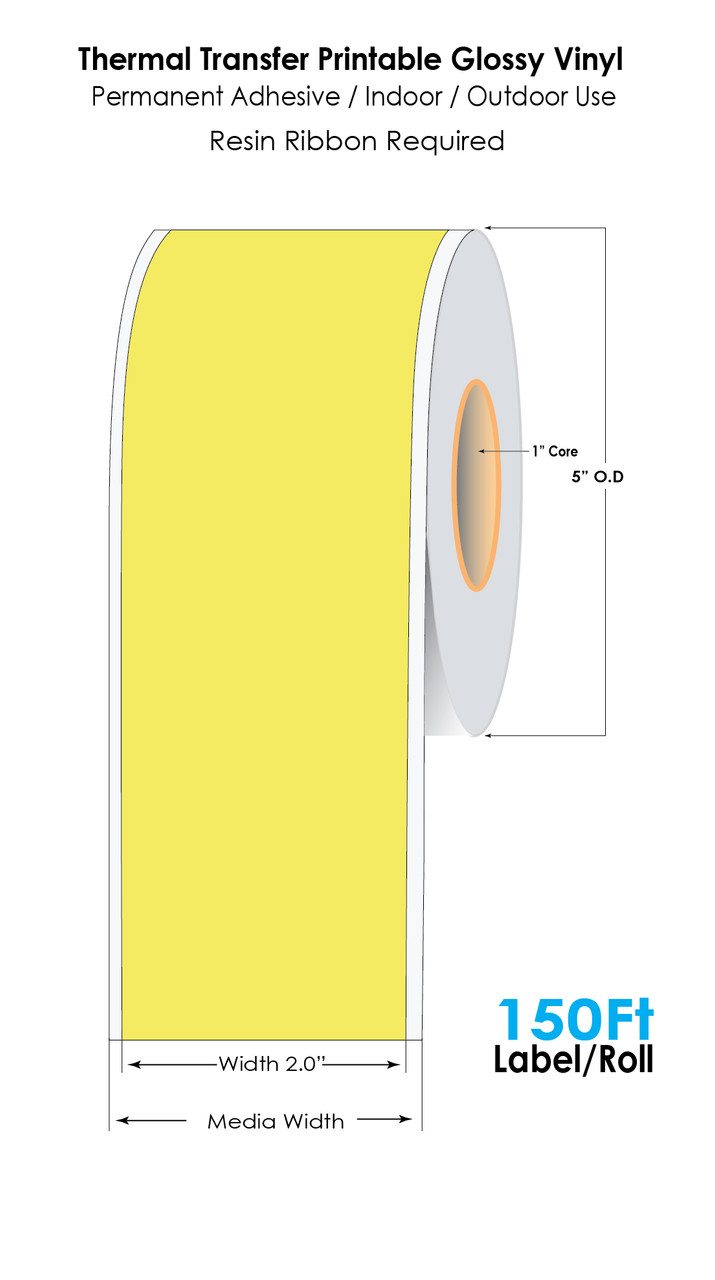

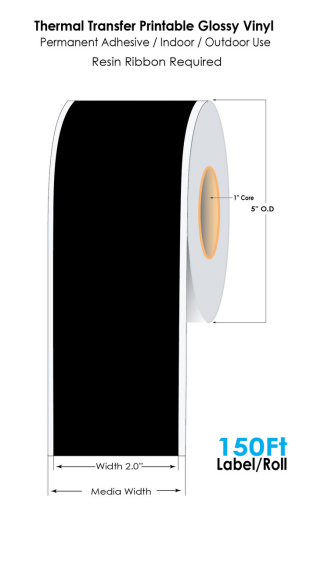

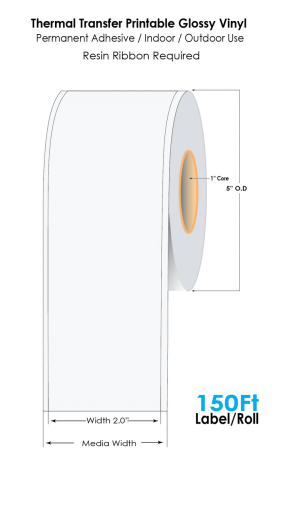

For instance, manufacturers can choose from a range of colored vinyl tapes depending on visibility and design needs:

- Clear 2” x 150 ft Glossy Vinyl Label Tape Roll – ideal for sleek, transparent branding or overlay protection.

- Black 2” x 150 ft Glossy Vinyl Label Tape Roll – a bold choice for high-contrast labeling and industrial-grade use.

- Yellow 2” x 150 ft Glossy Vinyl Label Tape Roll – perfect for warning signs, caution labels, or bright attention-grabbing visuals.

These premium vinyl tapes combine durability with high print quality, making them ideal for both product packaging and equipment labeling.

Polyester Labels: Chemical and Heat Resistant

Polyester labels are stiffer and provide excellent resistance to heat and chemicals. They’re commonly used on electronics, machinery, and industrial equipment that must retain identification in demanding conditions.

If your products are exposed to solvents, cleaning agents, or outdoor weather, polyester provides the longest-lasting protection.

Printing Technologies that Complement Weatherproof Labels

Weatherproof labels perform best when printed using the right technology. Two main systems dominate this space:

- Thermal Transfer Printing: This method uses a resin ribbon that transfers ink onto the label via heat. It creates crisp, long-lasting images that resist moisture and fading. Thermal transfer is perfect for barcodes, safety information, and inventory labels.

- Pigment Inkjet Printing: For full-color applications, pigment inkjet printers produce vibrant, fade-resistant designs. Unlike dye-based inks, pigment inks bond tightly to weatherproof materials, ensuring the label’s colors last as long as the product itself.

Businesses often combine both methods — using pigment inkjet for customer-facing product labels and thermal transfer for barcoding or compliance labeling.

When sourcing printers, small businesses can look for thermal label printers online or explore pigment inkjet label printers in Canada to find equipment that matches their workflow.

Real-World Applications of Weatherproof Labels

Weatherproof labels aren’t limited to one industry — they’re essential anywhere durability meets design.

Food and Beverage

From chilled bottles to frozen goods, condensation can ruin paper labels. Vinyl or polyester weatherproof labels stay intact through refrigeration, shipping, and consumer handling.

Health and Beauty

Cosmetics and personal care products often face moisture and handling. Weatherproof materials prevent smudging and preserve branding consistency.

Outdoor Equipment and Tools

Whether applied to construction tools, gardening supplies, or outdoor gear, weatherproof labels resist UV fading and abrasion from frequent use.

Industrial and Chemical Products

Warning and safety labels must remain legible even under harsh exposure. Vinyl and polyester options ensure compliance and product traceability over time.

Each of these industries depends on labels that communicate reliability — not just when the product is sold, but throughout its entire lifecycle.

Sustainability Considerations

Durable doesn’t have to mean wasteful. Advances in label material technology now allow weatherproof vinyl and polyester substrates to be produced with lower environmental impact. Long-lasting labels reduce replacement frequency, meaning less waste and fewer reprints.

Some manufacturers are also developing recyclable film-based labels and eco-friendly adhesives. Choosing the right supplier ensures that durability aligns with sustainability goals — a key factor for modern, environmentally conscious brands.

Testing Your Labels Before Full Deployment

Before committing to a large production run, businesses should test their weatherproof labels in real-world conditions.

- Moisture Testing: Apply labels to product samples and expose them to water or condensation.

- Temperature Testing: Simulate refrigeration or outdoor heat cycles.

- Chemical Testing: For industrial products, test against oils, detergents, or solvents.

- Handling Durability: Rub or scratch test the labels to see if the print holds up.

This ensures that your chosen label and printing method truly meet your durability requirements before scaling up.

The ROI of Investing in Weatherproof Labels

The upfront cost of weatherproof labeling may be higher than standard paper labels, but the payoff is significant. You eliminate the expense of damaged, unreadable, or rejected product batches — and more importantly, you protect your reputation.

When customers see consistent quality, even under extreme conditions, it builds confidence in your brand. Over time, this reliability translates into repeat business and stronger market trust.

Weatherproof labeling is a small upgrade that pays dividends in brand longevity.

Protect the Look That Protects Your Brand

Your label is often the first — and last — thing customers see. When it endures moisture, sunlight, and abrasion without fading, it silently reinforces your professionalism and commitment to quality.

Products like the clear, black, and yellow vinyl label tape rolls from DuraFast Label offer an ideal foundation for creating labels that last in any environment. Combined with the right printer and ribbon pairing, they deliver a perfect balance of beauty and strength.

If you’re looking to elevate your labeling with proven durability, DuraFast Label Company offers solutions for both vinyl and polyester label systems. Explore their full range of thermal label printers in Canada and weatherproof labels. For tailored recommendations or technical advice, explore their solutions or contact them to speak with an expert who can guide you toward the perfect setup.

About the Author

Elliot Fraser is a materials and packaging specialist with over 12 years of experience in industrial labeling and product design. He writes about durability, sustainability, and how small improvements in labeling can lead to lasting impressions and stronger brand identity.