Silicone rubber mold manufacturers are vital partners in industries that manufacture molds from prototypes to large-scale production. These specialized molders manufacture tough, flexible molds that can survive within extreme temperature ranges while retaining their dimensional stability- attributes that are vital in most demanding sectors from automotive engineering and aerospace technology to medical devices, food processing, and consumer products.

The manufacturing process is important in producing maximum consistency, detailed reproduction, and an increased product life span. Silicone rubber mold manufacturers provide customization services to both kinds of uses-from industrial-grade requirements to those that are food safe-and include small-batch specialty items to large-scale production runs. Sophisticated techniques assure that each mold will meet specifications but have the requisite durability to endure repeated use under high-pressure conditions.

This extremely specialized manufacturing combines the science of materials with precision engineering. The outcome of these efforts is producing solutions that meet the exacting standards that modern industrial applications require. Such products made by silicone rubber mold suppliers are a critical balance between today’s flexible industrial and structural integrity.

Texas-Based Manufacturing Advantages: Serving Local and Global Markets

Texas has localized its manufacturing location primarily for strategic benefits to regional and global clients. The strong industrial foundation of the state makes silicone rubber product manufacturers Texas a haven for sourcing high-quality raw materials along with well-skilled labour; its central geographic position in the United States also facilitates distribution throughout the country without any hassle.

The facility has specific expertise in serving the energy sector, such as specialized silicone molds for oilfield applications that will maintain performance status under extreme temperatures and exposure to corrosive chemicals. The leading silicone rubber mold manufacturers Texas ensures that products measure up to thorough quality and safety requirements. These geographies with technical specializations and quality certifications put the facility in a good position to meet a variety of industrial needs while maintaining requisite production standards. These capabilities allow the operation to maintain a high production standard, especially to the benefit of customers in sectors with very high demands, such as using durable, high-performance silicone components.

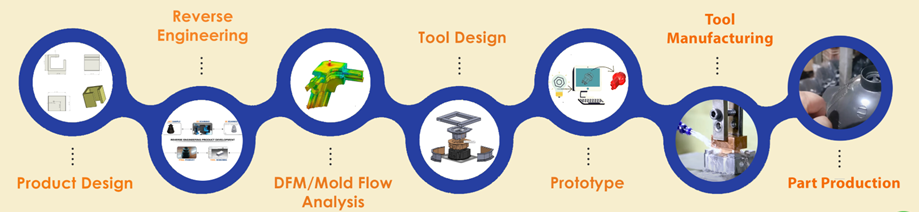

Manufacturing process as a mold manufacturer:

1.Venting product design into mold manufacturing and engineering.

At this stage, the first step in our process consists of collaborative design sessions that translating your visions into 3D CAD models, then thorough feasibility studies by our engineering team entail the know-how about the properties of the material (food-grade, medical grade, and rough industrial silicone), structural integrity, and production. Silicone mold manufacturer optimize every aspect-from wall thickness to surface finish-enduring both designs to be functional and manufacturable.

2. DFM and Mold Flow Analysis

Before we have commenced tooling, we are going to run advanced simulations to predict the tendency of a flow of material, its curing character, defects, and other issues. It is an important step to give the brilliant molding design free of waste for optimizing gate placement, venting, and cycle times. Silicone mould manufacturing services should allow to identify and resolve potential issues within the virtual environment, saving time and about cost.

3. Precision Tooling

This fully nuclear CNC machining center is manufacturing high-precision steel or aluminum molds, with precision tolerances as tight as may be required by the specialized specification. For very complex geometries, it is also utilizing EDM technology. Silicone rubber mold suppliers claim that surface hardening and polishing of every mold ensures an extremely long life and perfect reproduction of the surface.

4. Prototype Validation

We as Silicone rubber products manufacturer produce functional prototypes that can reserve confirmations of fit, form, and function, allowing us to make some design changes, adjustments, and material tests under real-life conditions before mass production.

5. Automated Production

The manufacturing floor is furnished with advanced LSR injection molding systems that direct high volumes for specialized applications using compression molding. Automated processes maintain consistency without compromising quality from one production run to another. This capability is a major reason we’re regarded as a leading silicone mold manufacturer, trusted for both precision and scale.

6. Strict Quality Control

Each batch is subjected to rigorous testing, which includes:

• Dimension checks with CMM

• Testing of material properties (durometer, tensile strength)

• Visual and functional verification

Only parts satisfying our rigid ISO-certified standards progress upward to packaging.

7. Global Distribution

We as Custom silicone molds manufacturer, offer customized packaging solutions as well as flexibility in logistics to meet the requirements of your supply chain-from just-in-time delivery to worldwide shipping. From medical devices to automobile components, our vertically integrated process guarantees excellence at all levels. Our end-to-end process ensures precision, efficiency, and reliability-from medical to automotive applications.

Industry-Specific Solutions: Meeting Unique Application Demands:

As an experienced silicone rubber products manufacturer, we have knowledge and expertise in many applications in various industries. The medical field is one where we manufacture cleanroom molding and implant-grade silicones for benign and biocompatible components of diagnostic and surgical devices. In the automotive industry, we make molds for high performance engine components while still retaining flexibility to withstand severe heat inside the engine compartment.

For the food industry, our nonstick mold made of silicone has great release characteristics and dimension stability after thousands of use cycles. Additionally, molds are used by other factories and industries, such as electronics-made protective housings and seals for sensitive components, and in construction, for forming durable gaskets, expansion joints, and weatherproofing materials. Their multi-use properties make silicone molds, perhaps, the most widely used mold in the industrial manufacturing environment today, as they are resilient, chemical-resistant, and design-flexible.

Sustainable Manufacturing Practices- Responsible Production:

Our operation is underpinned by our environmental responsibility. Silicone recycling programs have been established that collect and recycle much of the waste generated during manufacturing. These days, Silicone rubber products manufacturer have energy-efficient molding equipment to reduce power consumption, and we’ve switched to water-based release agents that reduce VOC emissions. We constantly study and evaluate new bio-silicone formulations that offer performance while being gentle to the environment. The essence of such initiatives is to save the planet, but typically, these also save money, which we pass on to our clients.

Innovation and Future Development:

Our engineering team is ever exploring innovative possibilities in silicone mold manufacturing procedure. Latest initiatives involve developing intelligent molds embedded with sensors for real-time performance monitoring. Another involves the experimentation of additive manufacturing techniques for hybrid mold production. Refining rapid tool development processes will lead to further reductions in prototype development lead times. All these efforts push the boundaries of what a silicone mold manufacturer can offer through technology enable our clients to have access to the most advanced solutions in silicone molding.

Why Choose Our Silicone Mold Manufacturing Services?

Joining us can assure you success. The knowledge in technology, the latest sophisticated equipment put together with customer-oriented service generates enormous value along all phases of your project. From conceptualization to maximum production, our solutions and support will surely translate your silicone product visions into reality with confidence and precision. So contact us ( +1(646)-814-4070 or mail info@rubbersiliconemolds.com) so that we talk on how we can help solve your molding-related problems or demands.