When it comes to hydraulic systems, two important components often get mentioned together—gear pumps and gear motors. At first glance, they may look similar and even share some design features, but their roles are quite different. If you’ve ever wondered what sets them apart, how they work, and when to use each one, this post will clear things up.

Let’s dive into the world of gear pumps vs gear motors and break it down in a simple, conversational way.

What is a Gear Pump?

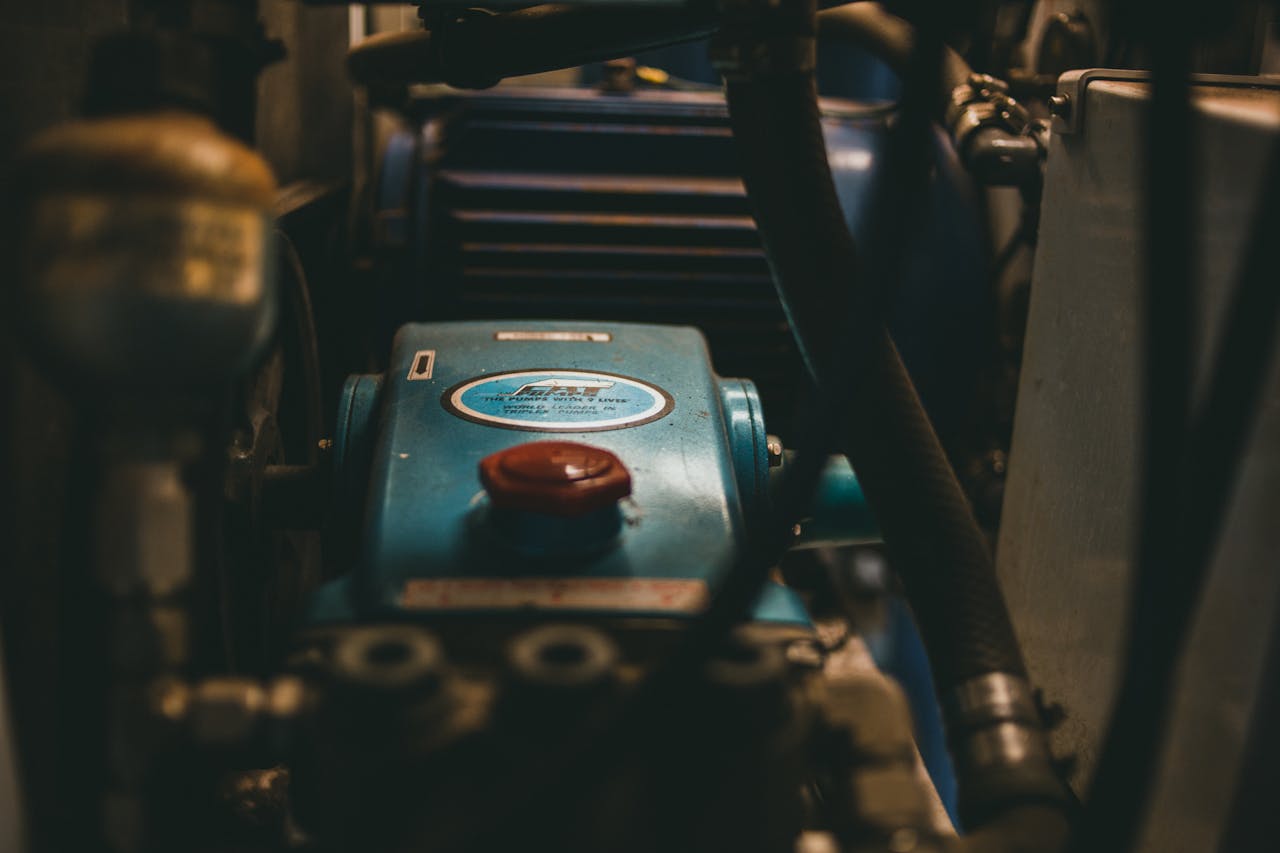

A gear pump is a type of hydraulic pump that moves fluid using the meshing of gears. It’s one of the most common types of hydraulic pumps because of its simplicity, durability, and reliability.

Here’s how it works in simple terms:

- Inside the pump, there are two gears that rotate.

- As the gears turn, they trap fluid between the gear teeth and the casing.

- The rotating gears then push the fluid around the casing and out through the outlet.

It’s like scooping water with a wheel—each turn moves a fixed amount of fluid.

Gear pumps are typically used when you need steady, continuous fluid flow at medium pressure levels.

What is a Gear Motor?

Now, let’s talk about gear motors. While gear pumps move fluid, gear motors do the opposite—they use hydraulic fluid to create rotary motion.

Here’s how it works:

- Pressurized fluid enters the motor.

- The fluid pushes against the gears, causing them to rotate.

- This rotation is then used to drive mechanical equipment, like conveyor belts, winches, or wheels.

In short:

- Gear pump = converts mechanical energy into fluid power.

- Gear motor = converts fluid power back into mechanical energy.

They’re like two sides of the same coin, working together in hydraulic systems.

Key Differences Between Gear Pump and Gear Motor

Even though gear pumps and gear motors share similar construction, their purposes are different. Let’s compare them side by side:

| Feature | Gear Pump | Gear Motor |

|---|---|---|

| Function | Moves fluid (creates flow) | Uses fluid to create motion |

| Energy Conversion | Mechanical → Hydraulic | Hydraulic → Mechanical |

| Direction | Usually one-way flow | Can be bi-directional |

| Pressure Handling | Medium to high pressure | Handles higher loads and torque |

| Applications | Hydraulic power units, lubrication systems | Winches, conveyors, mixers, drive systems |

So, while they may look alike, their jobs are not the same.

How Gear Pumps Work in Real Life

Gear pumps are found in countless applications. Some everyday examples include:

- Hydraulic power packs – Supplying pressurized fluid to machines.

- Lubrication systems – Circulating oil to reduce friction in engines.

- Chemical processing – Moving fluids like solvents or resins.

- Agricultural machinery – Operating hydraulic cylinders in tractors.

Their strength lies in simplicity. Gear pumps are compact, affordable, and require little maintenance, which is why industries rely on them so much.

How Gear Motors Work in Real Life

Gear motors take hydraulic power and turn it into rotational motion. You’ll find them in:

- Winches and cranes – To lift and move heavy loads.

- Conveyor belts – Driving continuous motion in manufacturing plants.

- Mixers and agitators – Rotating blades for mixing liquids.

- Construction equipment – Powering wheels, drills, and cutting heads.

The main advantage of gear motors is that they deliver high torque at low speeds, making them perfect for heavy-duty tasks.

Advantages of Gear Pumps

Gear pumps come with several benefits that make them reliable choices:

- Simple design → Easy to use and maintain.

- Durability → Long service life in tough environments.

- Steady flow → Ideal for applications needing consistent output.

- Cost-effective → Affordable compared to other hydraulic pumps.

- Compact size → Fits well in smaller systems.

Advantages of Gear Motors

Gear motors also have unique strengths:

- High torque → Excellent for heavy loads.

- Bi-directional operation → Can rotate in both directions.

- Compact and rugged → Suitable for mobile machinery.

- Reliable under high pressure → Can withstand tough operating conditions.

- Wide application range → From industrial machinery to mobile equipment.

When to Use a Gear Pump

Choose a gear pump if your goal is to:

- Move hydraulic fluid efficiently.

- Run lubrication systems where continuous oil circulation is needed.

- Supply fluid to hydraulic cylinders in machinery.

- Work with medium pressure requirements.

Gear pumps are your go-to option when you need fluid flow without too much complexity.

When to Use a Gear Motor

On the other hand, go with a gear motor if you need to:

- Drive mechanical loads with hydraulic power.

- Operate equipment that needs high torque at low speeds.

- Power conveyors, winches, or mixers.

- Handle tough, heavy-duty conditions.

In short, gear motors are for situations where motion and power are required, not just fluid flow.

Gear Pump vs Gear Motor: Working Together

Interestingly, in many hydraulic systems, gear pumps and gear motors work hand in hand.

- The gear pump generates hydraulic flow by converting mechanical energy into fluid energy.

- The gear motor then takes that hydraulic energy and turns it back into mechanical motion.

This cycle makes it possible to power machines with smooth, controlled motion.

A simple example: In a hydraulic crane, the gear pump pushes fluid into the system, while the gear motor drives the winch to lift heavy loads.

Challenges with Gear Pumps and Gear Motors

While both are reliable, they do come with some limitations:

- Gear Pumps: Not suitable for very high-pressure applications, can be noisy at times.

- Gear Motors: Efficiency can drop at very low speeds, may require regular checks.

However, with proper design, installation, and maintenance, these challenges are manageable.

Future of Gear Pumps and Gear Motors

As industries move toward smarter and more efficient systems, gear pumps and gear motors are also evolving. Future trends include:

- Energy-efficient designs to reduce power consumption.

- Quieter operation with advanced materials and precision engineering.

- IoT-enabled monitoring for predictive maintenance.

- Compact designs to save space in modern machines.

This means they’ll continue to play a key role in automation, construction, agriculture, and manufacturing.

Final Thoughts

So, what’s the difference between a gear pump and a gear motor?

- A gear pump moves fluid.

- A gear motor uses fluid to create motion.

They may look similar, but their functions are very different. The choice between them depends on your needs—whether you want to move fluid through a system or generate motion to power equipment.

In reality, many systems use both together, making them the perfect pair in hydraulic applications.

Next time you see a hydraulic crane, conveyor belt, or lubrication system in action, you’ll know whether it’s the gear pump or gear motor at work behind the scenes.