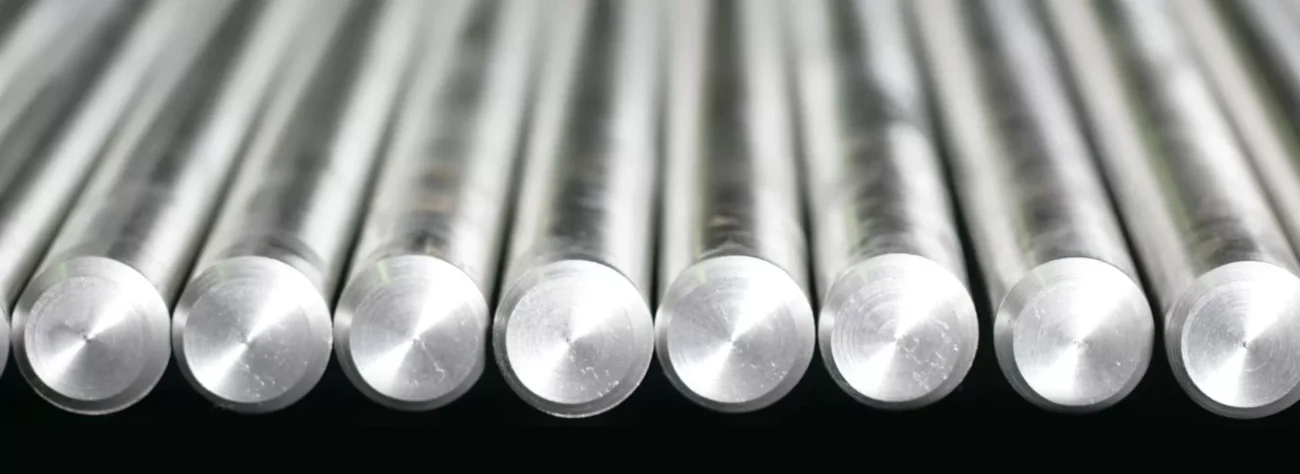

Inconel 600 is a material built to perform under the toughest conditions. Known for its exceptional strength, oxidation resistance, and corrosion tolerance, it has become a preferred choice for industries operating in demanding environments. As a leading Inconel 600 Bar Supplier, we deliver high-performance alloy bars that meet global quality standards and exceed industrial expectations.

This article explains everything you need to know about Inconel 600 bars from composition and characteristics to applications and benefits and why choosing the right supplier makes all the difference.

Understanding Inconel 600 Alloy

Inconel 600 (UNS N06600) is a nickel-chromium alloy designed for applications that require both corrosion and heat resistance. With a composition rich in nickel (minimum 72%) and chromium (14–17%), the alloy exhibits stability in a wide temperature range and resists attack by many organic and inorganic compounds.

It performs exceptionally well in oxidizing and reducing environments, which makes it suitable for a wide range of industries from aerospace to chemical processing. The alloy’s versatility, coupled with its mechanical strength, makes Inconel 600 bars a preferred material choice for engineers and manufacturers worldwide.

Chemical Composition of Inconel 600 Bars

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 72.0 min |

| Chromium (Cr) | 14.0 – 17.0 |

| Iron (Fe) | 6.0 – 10.0 |

| Manganese (Mn) | 1.0 max |

| Carbon (C) | 0.15 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.015 max |

| Copper (Cu) | 0.5 max |

This composition ensures high corrosion resistance, especially against chlorides, sulfides, and caustic alkalis.

Mechanical Properties of Inconel 600 Bars

| Property | Value |

|---|---|

| Tensile Strength | 550 MPa |

| Yield Strength (0.2% Offset) | 240 MPa |

| Elongation | 30% |

| Hardness | 160 HB |

These properties make Inconel 600 bars suitable for components that require excellent mechanical integrity at both high and low temperatures.

Key Features of Inconel 600 Bars

- Superior Corrosion Resistance:

Inconel 600 bars resist oxidation, corrosion, and scaling in a wide variety of environments, including acidic and alkaline conditions. - Excellent Heat Resistance:

The alloy retains strength and form at temperatures up to 1200°C, making it ideal for furnace parts and heat-treatment equipment. - Non-Magnetic:

The alloy remains non-magnetic across different temperatures, which is advantageous for electronic and aerospace applications. - High Strength and Toughness:

Even in high-pressure or thermal stress environments, the material retains mechanical stability. - Ease of Fabrication:

It can be formed, welded, and machined using standard techniques. - Resistant to Chloride Stress-Corrosion Cracking:

It performs better than many stainless steels in chloride-rich conditions.

Types of Inconel 600 Bars

We supply different types of Inconel 600 bars, each suited for specific industrial needs:

- Inconel 600 Round Bars – Ideal for general engineering and machining applications.

- Inconel 600 Square Bars – Used in structural and heavy-duty components.

- Inconel 600 Flat Bars – Commonly used in marine, furnace, and chemical plants.

- Inconel 600 Hex Bars – Widely used for fasteners, fittings, and valves.

- Inconel 600 Forged Bars – Designed for high-pressure applications.

Manufacturing Process of Inconel 600 Bars

- Melting and Casting:

The process starts with melting raw materials in a controlled environment to ensure chemical consistency. - Hot Rolling:

The cast billets are hot rolled to the desired diameter and shape. - Annealing:

The bars are heat-treated to improve ductility and relieve internal stress. - Pickling and Cleaning:

Surface impurities and scales are removed to ensure smoothness and purity. - Cold Finishing (Optional):

Bars can be cold drawn or centerless ground to achieve tighter tolerances. - Quality Inspection:

Every bar undergoes mechanical, chemical, and non-destructive testing before dispatch.

Specifications of Inconel 600 Bars

- Standards: ASTM B166 / ASME SB166

- Grade: Inconel 600 / Alloy 600 / UNS N06600

- Size Range: 3 mm to 300 mm diameter

- Length: Up to 6000 mm or customized

- Finish: Black, Bright, Polish, Peeled, Ground

- Form: Round, Square, Flat, Hex, Forged

Applications of Inconel 600 Bars

Inconel 600 bars are widely used in industries where resistance to heat, pressure, and corrosion is essential. Here are some key application sectors:

- Chemical Processing Industry:

Used in reaction vessels, heat exchangers, and evaporator tubes exposed to caustic and acidic environments. - Aerospace Industry:

Ideal for jet engines, turbine blades, and exhaust systems due to its heat resistance. - Power Generation:

Found in furnace components, boiler tubes, and steam generators. - Marine and Offshore:

Excellent resistance to saltwater corrosion makes it suitable for offshore oil and gas facilities. - Food Processing:

Used where hot acids and alkalis are encountered during production. - Electronics and Instrumentation:

Perfect for heating elements and thermocouple sheaths. - Nuclear Plants:

Withstands radiation and high temperatures in reactor systems.

Advantages of Using Inconel 600 Bars

- Exceptional oxidation and scaling resistance.

- Stable mechanical strength across wide temperature ranges.

- Long service life with minimal maintenance.

- Superior performance in both oxidizing and reducing environments.

- Easy to machine, fabricate, and weld.

- Cost-effective for long-term industrial operations.

Testing and Quality Control

As a reputed Inconel 600 bar supplier, we ensure all products meet international quality standards. Our quality checks include:

- Mechanical Testing (Tensile, Hardness, and Yield Strength)

- Chemical Analysis (Spectro or Wet Analysis)

- Ultrasonic and Eddy Current Testing

- Intergranular Corrosion Testing (IGC)

- Dimensional Accuracy Check

- Visual and Surface Finish Inspection

All bars are supplied with Mill Test Certificates (MTC) in compliance with EN 10204 3.1 standards.

Why Choose Us as Your Inconel 600 Bar Supplier

When it comes to sourcing high-performance alloys, experience and quality matter. Here’s why industries choose us as their trusted Inconel 600 Bar Supplier:

- Uncompromised Quality:

Our products are sourced from reputable mills and manufactured with precision. - Extensive Inventory:

We maintain a wide stock of Inconel 600 bars in different forms, sizes, and finishes. - Customization:

We provide tailored solutions based on client requirements from cut lengths to specific finishes. - Competitive Pricing:

By optimizing our supply chain, we offer high-quality bars at industry-best prices. - Global Reach:

We serve both domestic and international clients across Asia, Europe, and the Middle East. - Expert Support:

Our technical experts assist clients in material selection, grades, and application recommendations.

Maintenance Tips for Inconel 600 Bars

To ensure the longevity of your Inconel 600 bars:

- Store in a clean, dry area away from corrosive substances.

- Use appropriate handling equipment to prevent surface damage.

- Clean surfaces before machining or welding.

- Avoid prolonged exposure to oxidizing acids when not in operation.

Conclusion

Inconel 600 bars are a proven choice for industries that demand strength, heat resistance, and durability. Their ability to perform in harsh environments makes them invaluable in aerospace, chemical, power, and marine applications.