Precision and reliability define the backbone of modern engineering, medical, and instrumentation systems. Among the many components that ensure smooth functionality, stainless steel needle tubes play an essential yet understated role. Designed with fine tolerances and superior finishes, these tubes ensure accurate fluid or gas transfer across various applications.

As a leading stainless steel needle tube supplier, we specialize in providing premium-quality tubing solutions crafted to meet international standards. Whether for a medical device, analytical instrument, or industrial system, our stainless steel needle tubes deliver unmatched accuracy and durability.

What Are Stainless Steel Needle Tubes?

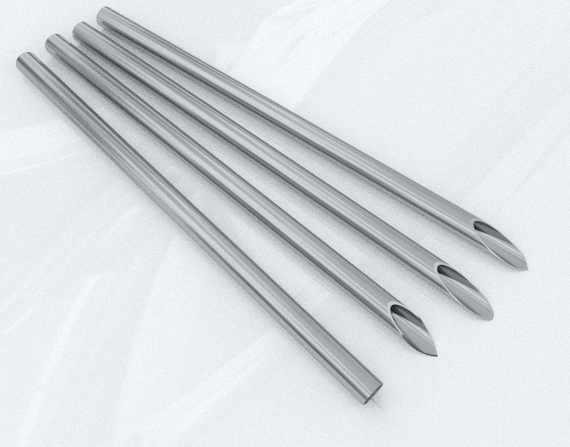

A stainless steel needle tube is a small-diameter, thin-walled tube designed for high-precision operations. It is typically used where accurate control of liquid or gas flow is essential. These tubes are made from corrosion-resistant stainless steel grades that ensure long life, even under harsh conditions.

Common grades used include SS 304, 304L, 316, and 316L, each offering excellent resistance to oxidation, pressure, and temperature variations. Their inner surface is polished to a mirror finish to ensure clean flow and reduce friction losses.

Stainless steel needle tubes are widely used in industries such as medical, pharmaceutical, chemical, automotive, aerospace, and instrumentation — wherever accuracy and strength are critical.

Key Features of Stainless Steel Needle Tubes

- Exceptional Corrosion Resistance

These tubes are resistant to rust, chemicals, and chlorides, making them suitable for both indoor and outdoor use. - Precision Engineering

Manufactured with tight tolerances for consistent dimensions, ensuring smooth and accurate performance. - Smooth Internal Finish

A fine internal polish allows friction-free flow and prevents contamination — ideal for medical and laboratory applications. - High Pressure and Temperature Tolerance

With excellent mechanical properties, these tubes can operate under demanding environments without deformation. - Hygienic and Biocompatible

Grades like 316L are safe for contact with biological materials and can be sterilized easily. - Easy Fabrication

They can be bent, cut, or welded to suit the required configurations without compromising structural integrity.

Grades of Stainless Steel Used in Needle Tubes

1. Stainless Steel 304

A commonly used grade offering good corrosion resistance and formability. It’s ideal for general industrial and structural applications.

2. Stainless Steel 304L

This low-carbon variant provides improved weldability and prevents carbide precipitation during welding.

3. Stainless Steel 316

With molybdenum added to the alloy, SS 316 delivers excellent resistance to chloride-induced corrosion, suitable for marine and chemical processing environments.

4. Stainless Steel 316L

The low carbon content enhances corrosion resistance and biocompatibility, making it perfect for medical and pharmaceutical applications.

Manufacturing Process of Stainless Steel Needle Tubes

Producing precision needle tubes requires advanced technology and a rigorous quality assurance process. The manufacturing typically follows these steps:

- Raw Material Selection

High-quality stainless steel billets are chosen based on the required grade and specifications. - Tube Drawing

The billets are drawn through dies multiple times to achieve the desired small diameter and thin wall thickness. - Annealing

Heat treatment helps relieve stress and restore ductility lost during the drawing process. - Pickling and Passivation

Surface treatments remove impurities and create a passive oxide layer that enhances corrosion resistance. - Polishing

Tubes are internally and externally polished to achieve a smooth surface, ensuring uninterrupted flow. - Testing and Inspection

Every tube undergoes dimensional inspection, non-destructive testing, and mechanical property checks to ensure flawless performance. - Cleaning and Packaging

Tubes are cleaned, capped, and packed securely to prevent contamination or damage during shipping.

Applications of Stainless Steel Needle Tubes

Because of their strength, precision, and corrosion resistance, stainless steel needle tubes are used across multiple industries:

1. Medical Industry

Used in needles, catheters, and surgical instruments due to their biocompatibility and non-reactive surface.

2. Analytical and Laboratory Equipment

Ideal for fluid transfer, chromatography, and chemical analysis systems requiring high precision.

3. Instrumentation Systems

Used in control panels, flow meters, and pressure gauges for accurate fluid measurement and control.

4. Automotive Sector

Employed in fuel injection systems, hydraulic lines, and brake systems for precision and safety.

5. Aerospace Industry

Used in high-pressure hydraulic systems and fuel lines where reliability is non-negotiable.

6. Food and Beverage Industry

Ensures hygienic transfer of liquids and gases, maintaining purity and preventing contamination.

7. Industrial Equipment

Used in process control systems, heat exchangers, and machinery where fine fluid regulation is essential.

Advantages of Stainless Steel Needle Tubes

- Superior Durability

Stainless steel ensures long service life even in corrosive or high-stress environments. - Corrosion and Oxidation Resistance

Performs well in chemical, marine, and industrial conditions. - Cost Efficiency Over Time

Requires minimal maintenance, reducing downtime and operational costs. - Consistent Performance

Precision manufacturing guarantees uniform flow and reliable operation. - Hygienic and Non-Toxic

Perfect for sensitive applications like food and medical sectors. - Customization Options

Available in a variety of diameters, wall thicknesses, and finishes according to project needs.

Quality Standards and Testing Procedures

As a trusted supplier, maintaining quality and consistency is our top priority. Our stainless steel needle tubes are produced according to international standards such as:

- ASTM A269 / ASTM A632 / ASTM A213

- EN 10216-5 / DIN Specifications

- ISO 9001 Certified Quality Systems

Each tube undergoes multiple quality checks, including:

- Hydrostatic Testing

- Eddy Current Testing

- Hardness and Tensile Strength Tests

- Visual and Dimensional Inspection

- Surface Roughness and Cleanliness Testing

These tests ensure that every tube meets or exceeds industry requirements.

How to Choose the Right Stainless Steel Needle Tube Supplier

When selecting a stainless steel needle tube supplier, consider these factors to ensure quality and dependability:

- Material Certification

Look for suppliers providing Mill Test Certificates (MTC) to verify composition and compliance. - Manufacturing Expertise

Choose a supplier with modern production technology and skilled professionals. - Quality Assurance

Ensure all tubes are tested and certified to meet international standards. - Inventory and Availability

Suppliers with a broad range of sizes and grades can meet urgent requirements efficiently. - Customization Options

A reliable supplier can provide custom lengths, finishes, and packaging as per your project’s needs. - After-Sales Service

Technical support and timely delivery are key indicators of a professional supplier.

Why We’re a Trusted Stainless Steel Needle Tube Supplier

As a premium stainless steel needle tube supplier, we deliver products that meet the highest performance expectations. Here’s what makes us a preferred partner across industries:

- Wide Range of Grades and Sizes:

We supply SS 304, 304L, 316, and 316L needle tubes in multiple dimensions and finishes. - Precision Manufacturing:

Our state-of-the-art production ensures accurate dimensions and excellent surface finishes. - Stringent Quality Testing:

Every tube undergoes rigorous inspections to guarantee durability and reliability. - Global Clientele:

We serve clients across the medical, pharmaceutical, automotive, and instrumentation sectors worldwide. - Competitive Pricing:

Our efficient manufacturing and logistics allow us to offer cost-effective solutions without compromising quality. - Customer-Centric Approach:

From inquiry to delivery, our focus remains on providing a seamless buying experience.

Conclusion

Stainless steel needle tubes may be small in size, but their importance in precision-based industries is immense. They ensure controlled fluid flow, structural integrity, and reliable operation in some of the most critical systems.