In the world of fluid and gas transfer systems, precision and reliability are non-negotiable. Among the many components used in piping assemblies, male connector tube fittings play an essential role in ensuring safe, leak-proof, and durable connections. These fittings are widely used across industries including oil and gas, petrochemical, power generation, food processing, and pharmaceuticals, where high pressure and temperature conditions demand superior performance.

What Are Male Connector Tube Fittings?

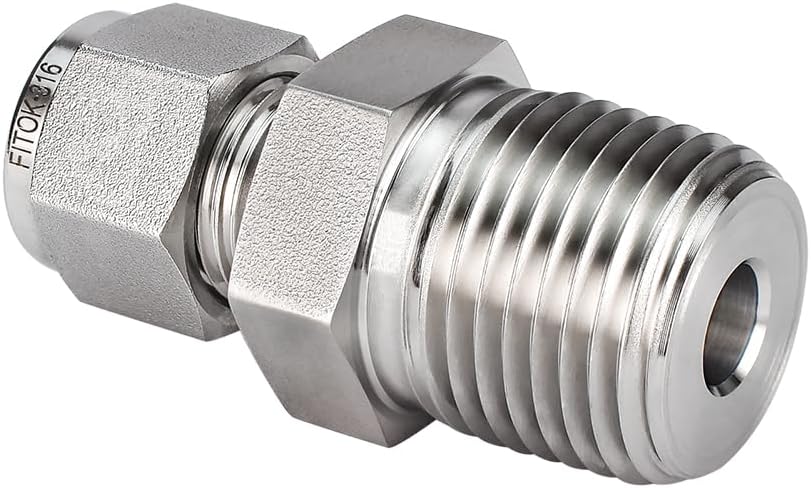

A male connector tube fitting is a mechanical component designed to connect a tube or pipe to another fitting, valve, or component within a system. It features a male thread that mates with a female thread to form a strong, sealed connection. These fittings are typically used in instrumentation, hydraulic, and pneumatic systems where maintaining leak-free operation is crucial.

The body of a male connector is engineered for durability, precision, and resistance to vibration and corrosion. They are usually made from materials like stainless steel, brass, copper, or alloy steel depending on the application requirements.

Key Features of Male Connector Tube Fittings

- Leak-Proof Design

These fittings are precision-machined with fine threads and accurate dimensions to ensure a tight seal, even under high pressure and vibration. - High Pressure and Temperature Resistance

Whether in hydraulic systems or gas pipelines, male connector tube fittings can withstand demanding operating environments without failure. - Corrosion Resistance

Stainless steel and nickel-alloy versions offer excellent resistance to rust and chemical attack, ensuring long-term reliability. - Ease of Installation

The fittings can be quickly installed and disassembled, allowing easy maintenance or reconfiguration of piping systems. - Compatibility

They are available in a variety of sizes, thread types (NPT, BSP, SAE), and configurations to suit global industry standards.

Types of Male Connector Tube Fittings

Depending on the system design, male connector tube fittings come in several variations, including:

- Straight Male Connectors: Used for direct, linear connections between tubes and components.

- Elbow Male Connectors: Ideal for connecting tubes at 45° or 90° angles to accommodate directional changes.

- Bulkhead Male Connectors: Used when connecting tubes through panels or walls, ensuring stability and alignment.

- Swivel Male Connectors: Allow movement while maintaining a leak-free seal, suitable for dynamic systems.

Each type is engineered for specific applications, ensuring optimal flow efficiency and mechanical integrity.

Industrial Applications of Male Connector Tube Fittings

The versatility and durability of male connector tube fittings make them indispensable across a wide range of industries:

- Oil and Gas: Used in fuel lines, pressure transmitters, and control panels.

- Chemical Processing: Suitable for corrosive and high-temperature chemical flow systems.

- Power Generation: Helps in hydraulic and cooling systems under extreme pressure.

- Pharmaceutical & Food Industries: Ensures contamination-free, hygienic flow connections.

- Aerospace & Automotive: Used in braking, fuel, and air systems where reliability is critical.

Advantages of Using Male Connector Tube Fittings

- Durable and Long-Lasting: Engineered with high-grade materials for long service life.

- Secure Connections: Prevents leakage and loosening, even under vibration or pressure changes.

- Maintenance Friendly: Easy assembly and reusability without the need for special tools.

- Enhanced Flow Efficiency: Smooth bore design minimises turbulence and pressure drops.

- Wide Material Selection: Available in stainless steel, brass, and other alloys to match system compatibility.

Why Male Connector Tube Fittings Are Critical in Modern Industries

In any fluid control system, the smallest component can determine overall efficiency. Male connector tube fittings might appear simple, but they are vital for ensuring mechanical strength, safety, and uninterrupted operation. The correct selection of fitting type, size, and material ensures consistent flow, reduced maintenance downtime, and increased system reliability.

As industries move toward automation and high-pressure applications, the demand for precision-engineered male connector tube fittings continues to rise. Their adaptability to various systems, combined with their ability to perform in extreme conditions, makes them one of the most reliable choices for modern industrial assemblies.

Conclusion

Male connector tube fittings are the backbone of reliable and efficient piping systems. Their ability to deliver leak-free performance, withstand harsh conditions, and provide long-term durability has made them indispensable in almost every industrial sector. When sourced from trusted manufacturers that adhere to global standards, these fittings ensure the safety, integrity, and performance of the entire system.