The growing industrial evolution which creates new market requirements demands advanced materials which improve product performance and product durability and product safety. The thermally conductive potting compound has emerged as a critical material used in electronics and automotive and industrial applications. The material provides essential component protection through its heat management capabilities which enable equipment to operate reliably in extreme working conditions.

Why Thermal Management Matters Today

All modern equipment produces heat because it is unavoidable. All devices from electronic circuits through power modules experience efficiency loss and component lifespan reduction from excessive heat. Effective thermal management helps companies maintain their equipment at safe operating temperatures which leads to better system performance. The need for sophisticated thermal solutions has grown in every manufacturing industry because systems now require greater power within smaller spaces.

The Purpose of Potting Compounds in Engineering

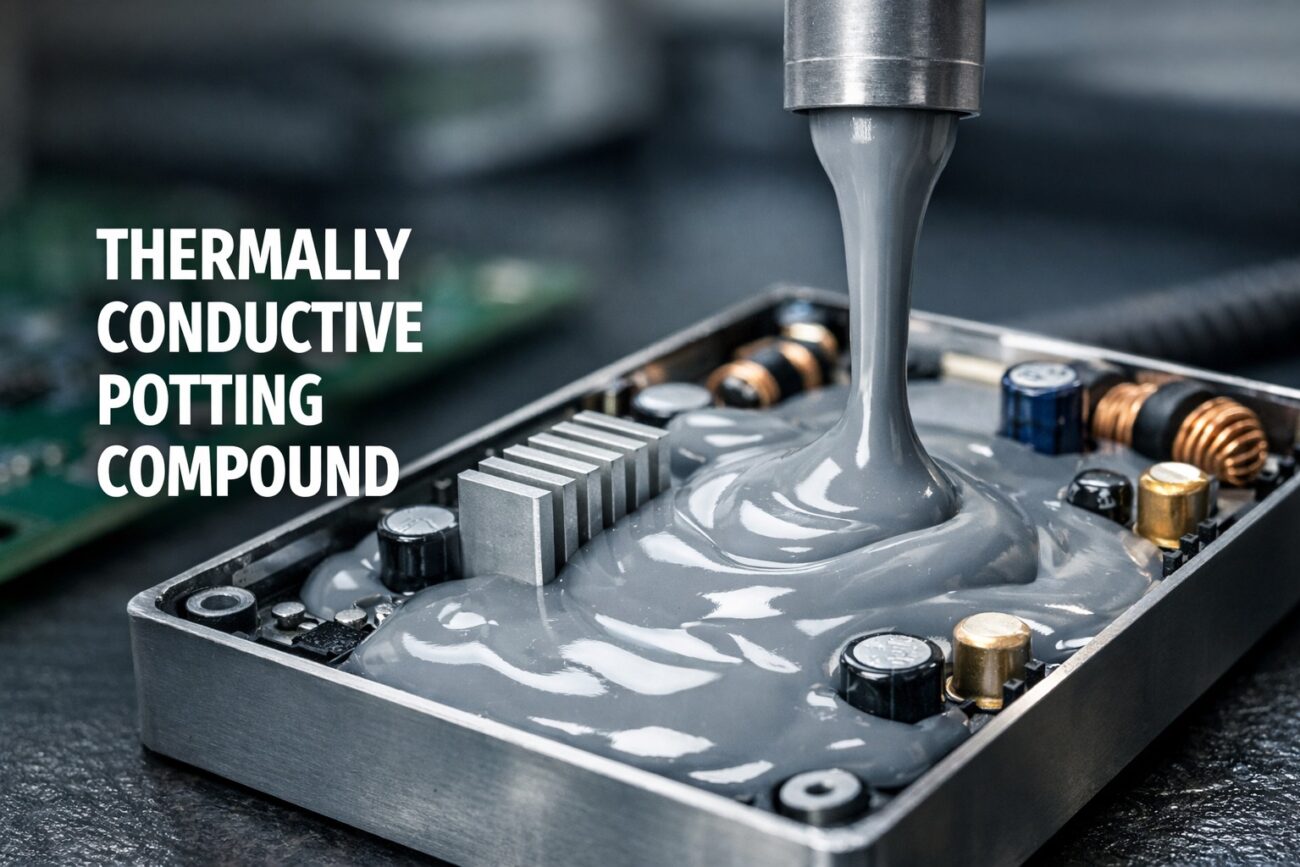

Potting compounds function as protective materials which seal electronic assemblies to create a barrier that protects against moisture dust and vibration and chemical contact. The compounds offer protection and deliver structural stability together with electrical insulation. The solution creates component protection which includes thermal conductivity as a means to enhance heat dissipation from protected components.

Key Considerations for Selecting the Right Compound

The selection process for the optimal thermally conductive potting compound needs to find proper equilibrium between its thermal performance and its mechanical characteristics. Engineers need to assess the compound’s compactness because it affects pouring ease and they need to test cure time to determine production efficiency and they must examine the coefficient of thermal expansion with the aim of making sure the compound expands at the same rate as the components it protects. The correct dielectric strength needs to be selected because it will guarantee electrical interference remains minimal while heat dissipation occurs to establish complete protection for the system.

How Thermally Conductive Formulations Support Performance

The thermally conductive potting compound functions as a specialized thermal management solution which effectively dissipates heat from essential components while achieving uniform heat distribution. The controlled heat transfer system decreases thermal stress which results in greater reliability and continuous operational efficiency for the system. The system requires these characteristics because its temperature changes directly affect system accuracy and safety during operation.

Applications Across Multiple Industries

Thermally conductive materials find extensive application in industries that require precise heat management. The electronics industry depends on these materials to produce circuit boards and sensors and power devices. Automotive systems use them in control units and lighting modules. The thermal stability of these compounds enhances the performance of renewable energy systems that include inverters and battery assemblies.

Enhancing Equipment Lifespan through Heat Control

The primary benefit of proper thermal management methods extends equipment lifespan through effective operation. The components experience faster deterioration when they encounter extreme temperature conditions which results in higher maintenance expenses and unplanned service interruptions. The combination of proper encapsulation and heat dissipation methods decreases equipment wear, which enables continuous operation at dependable performance levels throughout extended usage periods.

Supporting Safety and Operational Stability

Temperature control serves two functions which include achieving operational efficiency and maintaining protective measures. Overheating conditions lead to three different outcomes which include insulation breakdown and electrical faults and total system failure. Thermally conductive materials maintain continuous thermal conditions which decrease risks that come with operating at high temperatures. The maintenance of this stability serves a crucial purpose because critical environments require constant operational performance without exceptions.

Adapting to Technological Advancements

The ongoing technological progress leads to systems which have greater computational power and require smaller physical space. The thermal density problems increase because of the compact design which creates higher thermal density issues. Engineers now depend on materials which permit technological progress while maintaining system dependability.

Long‑Term Value for Manufacturing and Design

Investing in proper thermal protection supports long term efficiency and product quality. The operational results improve because reduced failure rates and improved reliability together with consistent performance create better outcomes. The integration of thermal solutions into design planning needs to happen at an early stage to achieve maximum system performance benefits.

Moving Toward Smarter Thermal Solutions

The selection of materials which provide heat management capability has become a strategic choice for businesses that pursue innovative industrial development. The operational performance of products develops through designers and manufacturers learning about the behavior of thermally conductive potting compound of their potting compound. Future business operations will achieve stable and efficient performance through the exploration of advanced thermal solutions.