In high-amperage power distribution, clarity is a safety requirement. When dealing with temporary power, backup generators, or load bank testing, you will frequently encounter two types of connection points: Power Input Panels and Power Output Panels.

While they look similar, their internal wiring and the direction of electricity flow are opposites. Using the wrong panel can lead to a dead short, equipment damage, or hazardous conditions for the operator. This guide explains the technical and practical differences to ensure you use the right hardware.

Defining the Direction of Flow

To understand these panels, you must define the electricity’s path relative to the building’s main distribution board.

What is a Power Input Panel?

A Power Input Panel (often called a generator docking station or an inlet box) is designed to receive electricity from an external source and feed it into the building’s electrical system.

When the utility grid fails, you connect a portable generator to this panel. The electricity flows from the generator, through the panel, and into your transfer switch to power your internal circuits. Because the panel is receiving power, it usually features “male” inlet connectors to prevent exposed, energized parts on the cable side when disconnected.

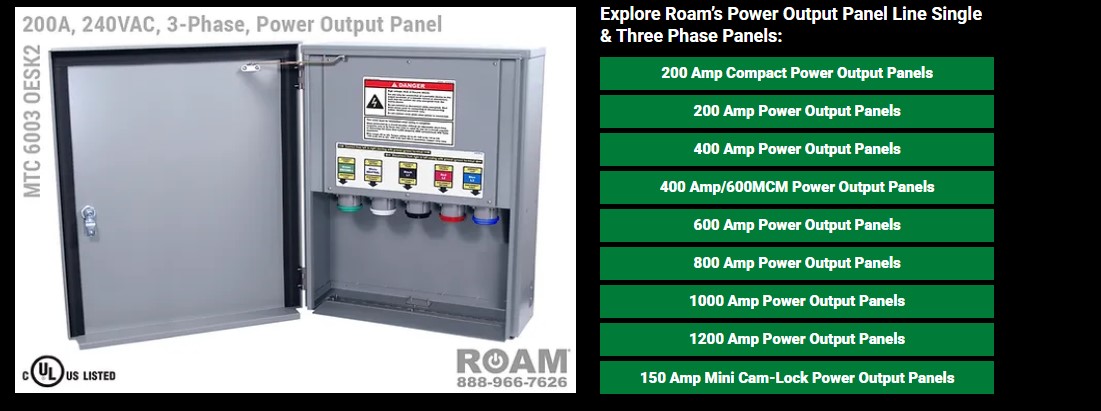

What is a Power Output Panel?

A Power Output Panel (sometimes referred to as a tap box or discharge panel) does the exact opposite. It is designed to take electricity out of the building’s system and provide it to an external load.

The most common use for an output panel is load bank testing. To verify that a building’s permanent standby generator is functioning correctly under a full load, you pull electricity from the system and send it to a load bank. In this case, the panel is the source of the power for the external device.

Key Technical Distinctions: Male vs. Female Connectors

The most visible difference between these two panels is the gender of the Cam-Lock connectors used inside the enclosure. This is a critical safety feature designed to prevent “hot” exposed metal.

- Input Panels (Inlets): These typically use Male Cam-Lock Inlets. The cable coming from the generator has female ends. When the cable is live, the energized parts are recessed inside the female connector. The male pins on the panel are only energized once the connection is made and the generator is running.

- Output Panels (Outlets): These typically use Female Cam-Lock Receptacles. Since the panel itself is the source of power (fed by the building’s breakers), the energized parts must be recessed (female) to prevent accidental contact by an operator.

Primary Use Cases

Understanding the application helps in choosing the right installation for your facility.

Scenario A: Connecting a Portable Generator (Input)

If a facility loses power and relies on a rental mobile generator, they need a Power Input Panel. The electrician plugs the generator into the male inlets of the panel. The power then travels to a Manual Transfer Switch, which disconnects the utility grid to prevent backfeeding.

Scenario B: Testing with a Load Bank (Output)

Hospitals and data centers are often required to test their emergency backup systems under load. To simulate a full building load without risking sensitive equipment, they connect a load bank to a Power Output Panel. The building’s generator runs, and the electricity is directed into the load bank via the output panel.

Safety Standards and Installation

Both types of panels must adhere to strict safety standards, primarily NEC Article 702 for optional standby systems.

- Interlocks: Input panels used for generators must be used with a transfer switch or an interlock kit. It must be physically impossible for generator power and utility power to meet.

- Overcurrent Protection: Output panels must be protected by a dedicated circuit breaker. Since you are pulling power out of the system, that circuit must be rated for the ampacity of the panel (e.g., a 400 Amp panel needs a 400 Amp breaker).

- NEMA Ratings: Since these panels are often mounted on the exterior, they should have a NEMA 3R rating to remain rainproof.

Common Mistakes to Avoid

- Reversing the Hardware: Installing an output panel where an input panel is needed. This forces the use of a “suicide cord” (male-to-male cable), which is a lethal safety violation.

- Improper Labeling: Failing to clearly mark the panel as “INPUT” or “OUTPUT.” In an emergency, a technician might attempt to feed power into an output panel, which could backfeed the system incorrectly if not properly breakered.

FAQ

Can I use one panel for both input and output? No. Because the connector genders are specific to the direction of the “source” power for safety reasons, you cannot safely use a standard panel for both. You should install dedicated panels for each function.

What happens if I connect a generator to a Power Output Panel? If the panel is correctly breakered and the breaker is on, you could technically backfeed the building. However, this is extremely dangerous because the cable coming from the generator would need to have male ends, creating exposed live pins. It is a major code violation.

Do I need a 1200 Amp panel for a small business? No. Panel sizes should match your anticipated load. Common sizes include 200 Amp, 400 Amp, and 800 Amp. For most small to mid-sized businesses, a 400 Amp Power Input Panel is the standard for mobile generator backup.