Polypropylene (PP) woven fabric has emerged as a cornerstone in the world of industrial and commercial packaging. Its unique blend of strength, flexibility, and affordability makes it an ideal choice across numerous sectors, including agriculture, construction, chemicals, and retail. This fabric, produced through advanced weaving techniques, offers durability and customization options that meet the demands of diverse applications. As industries continue to evolve and seek more sustainable and reliable materials, the role of a trusted PP fabric manufacturer becomes increasingly vital. Whether supplied as a PP woven fabric roll or transformed into sacks and bags, this material is redefining standards in packaging and infrastructure.

Understanding the Manufacturing Process and Core Traits of PP Woven Fabric

The creation of PP woven fabric begins with the extrusion of polypropylene pellets into fine tapes, which are then woven into large sheets using sophisticated weaving machines. The process allows for precise control over the fabric’s thickness, strength, and finish. Additional treatments such as coating, lamination, or printing can be applied to enhance specific properties like water resistance, UV protection, or branding. The resulting fabric boasts impressive tensile strength, tear resistance, and chemical stability. Its lightweight nature combined with high durability makes it suitable for heavy-duty applications, ensuring that goods remain protected during transit and storage. Partnering with an experienced pp fabric manufacturer guarantees access to high-quality, tailored products that meet exact industry standards.

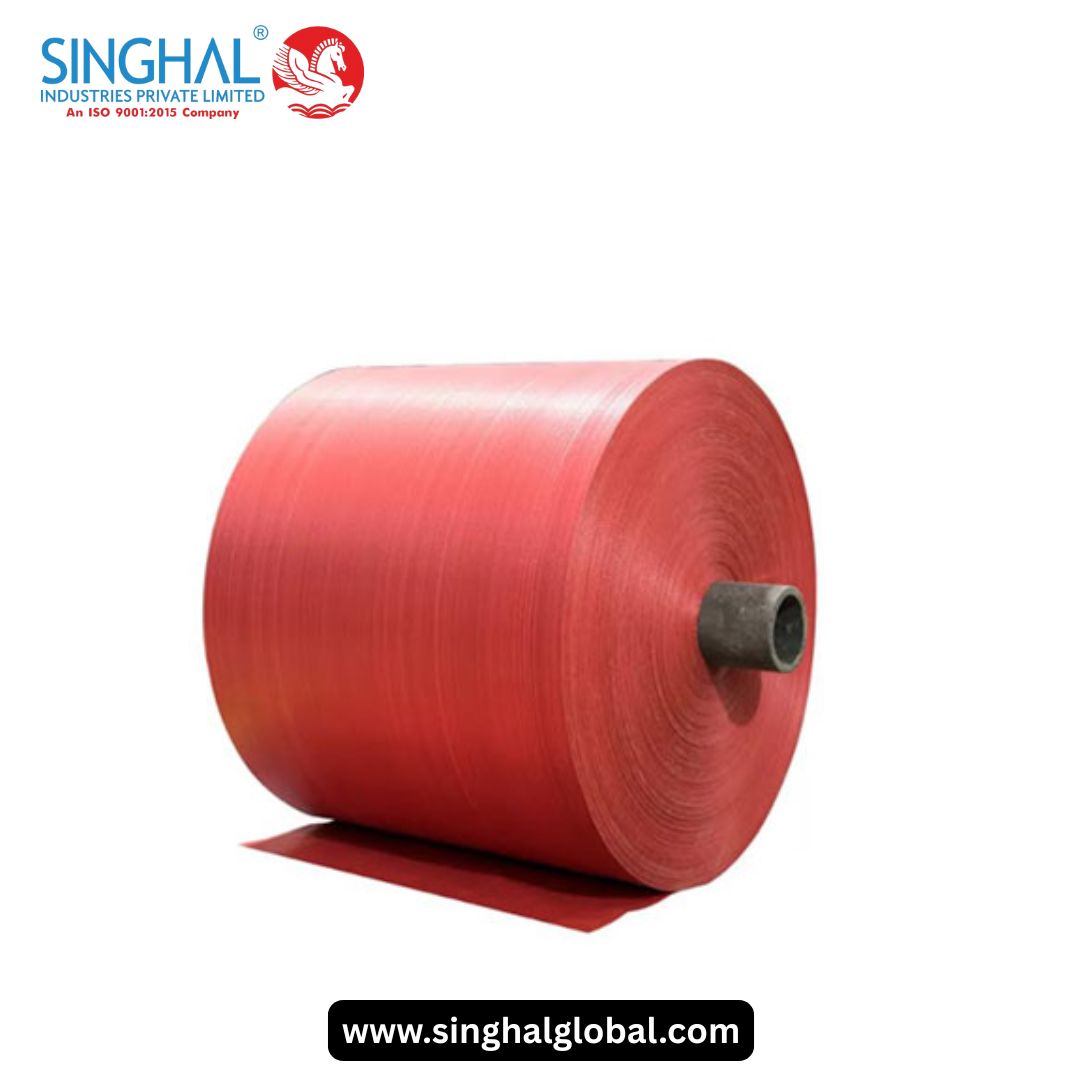

The Significance of PP Woven Fabric Rolls in Bulk Packaging

One of the most popular formats of PP woven fabric is the roll. Supplied in large rolls, this format offers unmatched convenience for bulk packaging operations. It allows manufacturers and traders to customize the fabric dimensions according to specific product sizes, reducing waste and optimizing costs. The roll format facilitates easy storage, handling, and transportation, especially for large quantities. Its resistance to moisture, chemicals, and UV rays ensures that stored items—be it grains, fertilizers, or minerals—remain unaffected by environmental factors. Additionally, printing options on PP woven fabric rolls enable brands to showcase their logos or product details prominently, enhancing brand visibility. Sourcing these rolls from reputable PP woven sacks manufacturers in India guarantees consistent quality, durability, and performance.

India’s Leading PP Woven Sacks Manufacturers: Quality and Innovation

India has established itself as a global hub for manufacturing high-quality PP woven sacks and fabrics. Renowned PP woven sacks manufacturers in India leverage cutting-edge weaving, coating, and printing technologies to produce sacks that are water-resistant, tear-proof, and capable of handling heavy loads. These manufacturers emphasize eco-friendly practices, using recyclable raw materials and sustainable processes that align with global environmental standards. The products are highly customizable, catering to various industries like agriculture, chemicals, and construction. India’s competitive pricing, combined with a commitment to quality, makes its PP woven sacks a preferred choice worldwide, ensuring reliable and eco-conscious packaging solutions.

Diverse Applications of PP Woven Fabric in Various Industries

The versatility of PP woven fabric is one of its greatest strengths. In agriculture, it is used for making silage bags, crop covers, and fertilizer sacks, thanks to its breathability and durability. In the construction sector, woven geotextiles serve for soil stabilization, erosion control, and drainage systems. Retailers rely on PP woven bags for packaging textiles, electronics, and consumer goods, benefiting from their customizable branding options. The chemical and mineral industries use coated or laminated PP woven fabric rolls to package moisture-sensitive or corrosive materials. Its resistance to environmental stressors and adaptability to treatments like anti-slip or UV stabilization make it suitable for even the most demanding applications.

Choosing the Right PP Fabric Manufacturer for Quality Assurance

Selecting a reliable pp fabric manufacturer is crucial for ensuring product quality, consistency, and adherence to industry standards. A reputable manufacturer should provide transparency regarding their sourcing, production processes, and quality assurance certifications, such as ISO. Customization options, including specific widths, thicknesses, coatings, and printing capabilities, allow businesses to tailor products to their needs. Working with established manufacturers ensures that the fabric you receive is durable, eco-friendly, and capable of handling your specific application requirements. A focus on innovation, sustainability, and customer satisfaction helps build long-term partnerships that support business growth and operational efficiency.

Conclusion: Innovation and Sustainability in PP Woven Fabric

PP woven fabric continues to evolve as a sustainable and innovative material that meets the changing needs of global industries. Its strength, flexibility, and eco-friendly potential make it a sustainable solution for packaging and infrastructural applications. Leading PP fabric manufacturers are now developing biodegradable and recyclable options to further enhance its environmental credentials. From large PP woven fabric rolls to specialized sacks, this fabric adapts seamlessly to diverse industry demands. Indian PP woven sacks manufacturers exemplify this progress, delivering eco-conscious, high-quality solutions to international markets. Investing in top-tier PP woven fabric guarantees secure product packaging, brand promotion, and environmental responsibility—marking a step toward smarter manufacturing practices.

Frequently Asked Questions

- What makes PP woven fabric suitable for heavy-duty packaging?

Its high tensile strength and tear resistance enable it to securely hold heavy loads without breaking. - Can PP woven fabric be customized for different industries?

Yes, it can be tailored with specific sizes, coatings, printed logos, and reinforcement to suit various applications. - Is PP woven fabric environmentally friendly?

Polypropylene is recyclable, and many manufacturers now produce biodegradable variants to reduce environmental impact. - Which sectors predominantly use PP woven fabric?

Agriculture, construction, chemicals, retail, and logistics are the primary industries relying on this versatile fabric. - How durable is a PP woven fabric roll?

If properly treated and stored, a high-quality roll can last several years, especially with UV and weather-resistant coatings. - Is PP woven fabric suitable for packaging moisture-sensitive items?

Yes, especially when coated or laminated, it provides excellent moisture and chemical resistance. - Can branding be printed on PP woven fabric?

Absolutely, printing on woven fabric is common and effective for advertising, branding, and product information. - What should I look for in a PP fabric manufacturer?

Look for certifications, consistent quality, customization options, eco-friendly practices, and industry experience. - Is the production of PP woven fabric sustainable?

It can be, especially when produced using recyclable materials and environmentally conscious manufacturing processes. - Where can I find the best PP woven fabric rolls?

Reliable suppliers include established PP fabric manufacturers and prominent PP woven sacks manufacturers in India, known for quality and innovation.