The photonics industry continues to drive innovation across telecommunications, biomedical research, and industrial applications through increasingly sophisticated optical components. As system requirements become more demanding, the need for specialized fiber optic solutions that deliver exceptional coupling efficiency and precise light control has never been greater. Engineers and researchers today require components that meet stringent performance specifications while providing the reliability necessary for mission-critical applications.

Advancements in Fiber Optic Technology

Modern photonics applications demand optical solutions that can efficiently transfer light between different components while maintaining signal integrity and minimizing losses. The evolution of fiber optic technology has led to significant improvements in coupling efficiency, beam quality, and manufacturing precision. These advances enable complex optical systems to operate with greater reliability and performance than ever before.

Technological progress in laser processing, precision polishing, and advanced materials has revolutionized how optical fibers are manufactured. Contemporary manufacturing techniques allow for precise control over fiber geometry, enabling the creation of specialized components tailored to specific application requirements.

Understanding Tapered Fibers Assemblies

Tapered fibers assemblies represent a sophisticated approach to mode field diameter modification and coupling optimization. These specialized components feature carefully controlled diameter variations that enable efficient light transfer between optical systems with different mode field characteristics. The tapering process involves precise reduction of both core and cladding diameters to achieve optimal beam expansion or compression.

Manufacturing these components requires advanced processing techniques that maintain fiber integrity while achieving precise geometric specifications. The adiabatic tapering process ensures minimal power loss during mode field transformation, making these assemblies essential for applications requiring high coupling efficiency.

The Role of Lensed Fibers Pigtails in Precision Applications

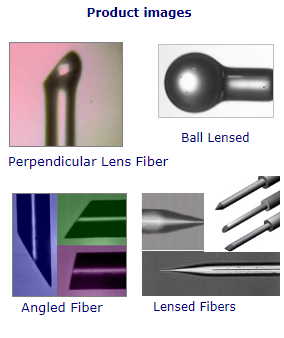

Lensed fibers pigtails provide essential functionality for applications requiring focused light delivery or enhanced coupling efficiency. These components feature precisely shaped fiber endfaces that act as integrated lenses, offering superior control over beam characteristics compared to standard flat-cleaved fibers. The lens geometry can be optimized for specific applications, whether requiring tight focusing or controlled beam expansion.

Manufacturing processes utilize advanced laser shaping technologies that create optimal lens geometries with exceptional repeatability. The integration of factory-terminated connectors provides convenient system integration while maintaining the precision necessary for high-performance applications.

Benefits and Use Cases Across Industries

Specialized fiber optic components deliver measurable benefits across diverse industry sectors. In telecommunications, enhanced coupling efficiency translates to improved signal quality and system reliability. Research laboratories benefit from the precision and repeatability these components provide for experimental setups. Industrial applications leverage their durability and consistent performance.

The biomedical sector particularly benefits from these advanced solutions, where precise light delivery is crucial for diagnostic and therapeutic applications. Defense and aerospace applications rely on their performance under challenging environmental conditions.

Why Quality and Customization Matter

The demanding requirements of modern photonics applications necessitate components manufactured to exacting standards. Quality control processes ensure consistent performance across production batches, while customization capabilities enable optimization for specific application requirements. This combination allows engineers to achieve optimal system performance while maintaining cost-effectiveness.

Partnering with experienced manufacturers provides access to technical expertise and manufacturing capabilities that ensure project success. The ability to collaborate on custom solutions enables the development of specialized tapered fibers assemblies and lensed fibers pigtails that meet unique application requirements while maintaining the performance standards demanded by professional applications.