In today’s competitive industrial landscape, sheet metal manufacturing plays a pivotal role in producing high-quality components for automotive, aerospace, electronics, and construction sectors.

But with evolving technology and stringent quality requirements, achieving precision in sheet metal manufacturing is more critical than ever.

Whether you’re running a small workshop or a large-scale manufacturing unit, understanding the key precision points can make all the difference in product quality, efficiency, and customer satisfaction.

Here’s an in-depth look at the essential precision points sheet metal manufacturers should consistently check:

1. Material Selection and Thickness Accuracy

The foundation of precision starts with the material itself. Choosing the correct type of metal—stainless steel, aluminum, copper, or carbon steel—is crucial, depending on the application.

Equally important is thickness accuracy. Even a minor deviation in sheet thickness can lead to assembly issues, weak points, or functional defects.

Tips:

- Verify material certifications before production.

- Use precise measuring tools like micrometers and thickness gauges.

- Consider tolerances specified by design engineers.

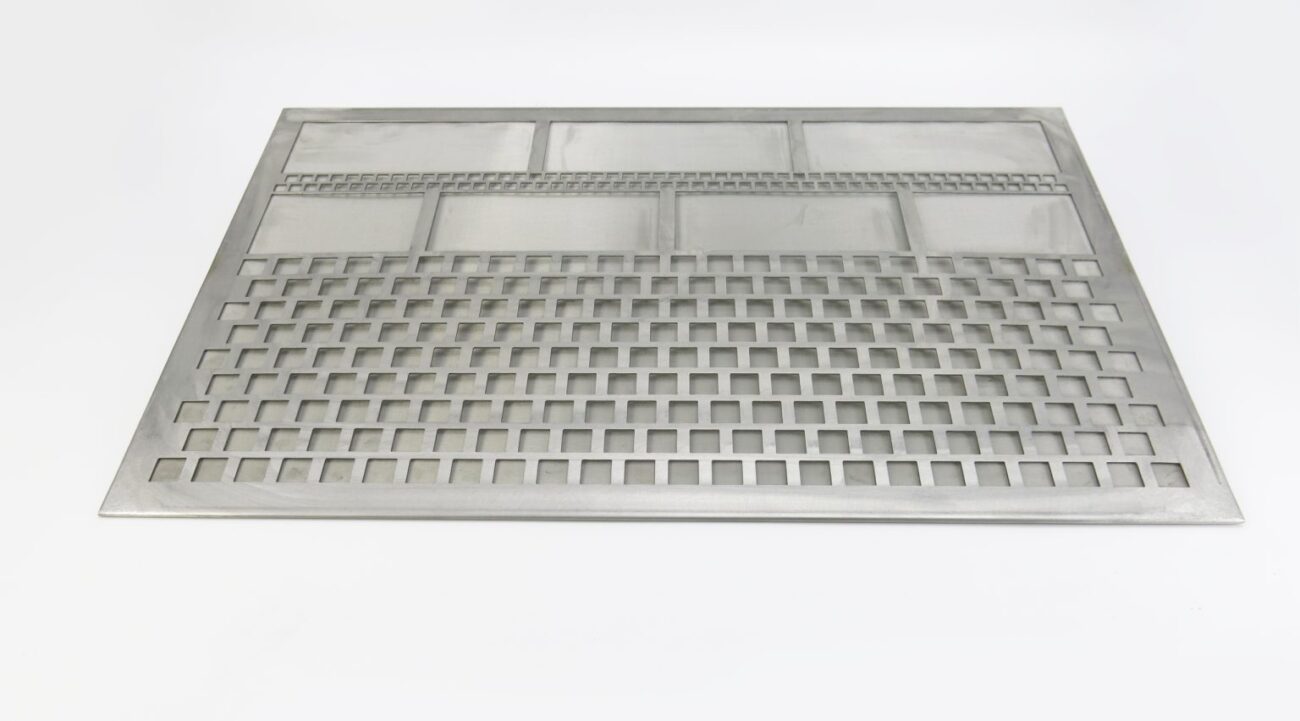

2. Dimensional Accuracy and Cutting Precision

Whether cutting sheets with laser, plasma, or mechanical shears, dimensional accuracy ensures that each part fits perfectly in the final assembly. Misaligned cuts or irregular shapes can result in material wastage and increased costs.

Tips:

- Regularly calibrate cutting machines.

- Implement automated cutting systems for repeatable precision.

- Inspect sample pieces for dimensional compliance before full-scale production.

For Bay Area sheet metal manufacturing, you need a professional like Mac Cal to ensure precise cutting, along with complete accuracy with finishes.

3. Bending and Forming Precision

Bending and forming are critical processes in sheet metal manufacturing, directly affecting product functionality. The correct bend angle, radius, and alignment determine how well parts fit together. Errors here can cause stress points, cracking, or deformation.

Tips:

- Use CNC press brakes for consistent bend accuracy.

- Check spring-back effects and adjust tooling accordingly.

- Conduct test bends on sample sheets before mass production.

4. Surface Finish and Quality Control

A flawless surface finish is not just about aesthetics—it affects corrosion resistance, paint adhesion, and component longevity. Precision in surface quality ensures that the final product meets functional and visual standards.

Tips:

- Inspect sheets for scratches, dents, or imperfections before processing.

- Implement regular cleaning and maintenance of machinery.

- Apply proper finishing techniques like polishing, deburring, or coating.

5. Tolerance and Compliance Checking

Precision is meaningless without adhering to specified tolerances. Every project comes with design tolerances for thickness, width, hole placement, and angles. Regular verification ensures parts meet design specifications and industry standards.

Tips:

- Maintain a quality control checklist for each production stage.

- Use coordinate measuring machines (CMM) for high-accuracy inspections.

- Train staff to detect and correct deviations immediately.

6. Tooling and Machine Maintenance

Even the most advanced sheet metal processes can fail if the tools and machines are not maintained properly. Dull blades, worn dies, or misaligned machinery can compromise precision.

Tips:

- Implement a preventive maintenance schedule.

- Regularly inspect tooling for wear and tear.

- Ensure machine calibration is conducted according to manufacturer guidelines.

7. Inspection and Testing Protocols

Finally, rigorous inspection and testing are essential to ensure precision and compliance with client requirements. This includes dimensional checks, structural integrity testing, and quality certification.

Tips:

- Use a mix of visual inspection, measurement tools, and automated inspection systems.

- Document all quality checks for traceability.

- Conduct periodic audits to improve precision standards continuously.

Conclusion

Precision in sheet metal manufacturing is a combination of material selection, machine calibration, employee expertise, and rigorous quality control. By consistently checking these precision points, manufacturers can reduce waste, improve product quality, and increase customer satisfaction.

At Mac Cal, we overcome the challenges with Austin vertically integrated manufacturing with modern processes. From advanced machinery to expert guidance, we help industries achieve the highest standards of precision and efficiency.