For automotive service centers, efficiency is everything — from accurate maintenance tracking to clear customer communication. One small but powerful tool helping auto shops stay organized and improve customer retention is the oil change label. These compact reminders play a surprisingly large role in brand professionalism, customer trust, and service consistency.

Whether printed on-site using a thermal label printer in Canada or ordered as pre-printed rolls, oil change labels give every customer a personalized reminder for their next visit. In this guide, we’ll explore how these labels streamline workflows, enhance client relationships, and how modern printers make implementing them easier than ever.

Why Oil Change Labels Are Essential in Automotive Operations

An oil change label may seem like a minor detail — a small sticker applied to a windshield or under the hood. Yet, for service shops, it’s one of the most visible connections between brand and customer.

Each label communicates vital information:

- The date and mileage of the next recommended service.

- Oil type, viscosity, or specific notes for the vehicle.

- The shop’s name, contact details, and logo for easy recognition.

When printed clearly and professionally, this label functions as both a maintenance record and a marketing touchpoint. Customers glance at it every time they drive, reinforcing brand recall and trust.

Without reliable labeling, shops risk confusion, missed appointments, and lost repeat business.

The Role of Custom Oil Change Labels

Customization is where oil change labels truly shine. Generic stickers might convey information, but custom-printed options elevate professionalism while reflecting the shop’s brand identity.

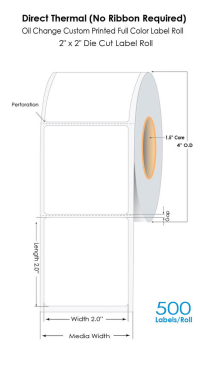

The Oil Change 2.0″ x 2.0″ Custom Printed Colour Label Roll (500/Roll) is a perfect example. These labels allow service centers to include their logo, brand colors, and specific layouts that suit their workflow. With full-color customization and adhesive optimized for glass or dashboard surfaces, they make a lasting impression — literally and figuratively.

Custom labels aren’t just about branding. They support accuracy, ensuring that service details are clear, durable, and easy for technicians and customers to read at a glance.

Key Benefits of Using Oil Change Labels

1. Improved Customer Communication

Oil change labels provide a simple, reliable way to remind drivers of their next service appointment without relying solely on digital systems. While text or email reminders are useful, the physical label acts as a visual nudge every time a customer drives.

2. Operational Consistency

Standardizing how service intervals are recorded and displayed helps technicians maintain consistency across multiple bays or locations. This improves communication between staff, especially when vehicles are serviced by different technicians.

3. Enhanced Brand Perception

A well-designed label communicates attention to detail. When customers see crisp, high-quality printing, it signals professionalism and care — traits that inspire confidence in any service business.

4. Reduced Administrative Errors

By printing labels directly from a digital service record, shops minimize handwriting errors and ensure each customer’s details are correctly transcribed.

Printing Options: Pre-Printed vs. On-Demand

Auto shops can choose between ordering pre-printed oil change labels or producing them in-house using a compatible printer.

Pre-Printed Rolls

Pre-printed labels like the Oil Change 2.0″ x 2.0″ Custom Colour Roll are ideal for shops that want a polished, branded appearance with minimal setup. These rolls are professionally produced for optimal adhesion and color accuracy.

On-Demand Printing

For more flexibility, many service centers are now adopting in-house printing solutions. Devices like the TSC TTP-225 2” Thermal Transfer Label Printer Oil Change Kit allow technicians to print custom oil change stickers on the spot.

This approach offers several advantages:

- Customization per customer: Easily adjust date, mileage, or notes.

- No delays: Print labels instantly as services are completed.

- Cost control: Avoid ordering in bulk or managing large inventories.

- Brand flexibility: Update logos, promotions, or QR codes as needed.

With direct connectivity to service software, technicians can print labels with accurate customer data in seconds — no manual handwriting required.

Label Material and Durability Considerations

The environment inside a car demands robust labeling. Heat, sunlight, and cleaning chemicals can easily degrade poor-quality stickers. Choosing the right label stock ensures longevity and readability.

- Thermal Transfer Labels: Ideal for windshield placement due to their smudge-resistant print and durable adhesive. They withstand temperature fluctuations and UV exposure.

- Polypropylene (BOPP) Labels: Provide water and oil resistance, ensuring labels remain intact even after multiple cleanings.

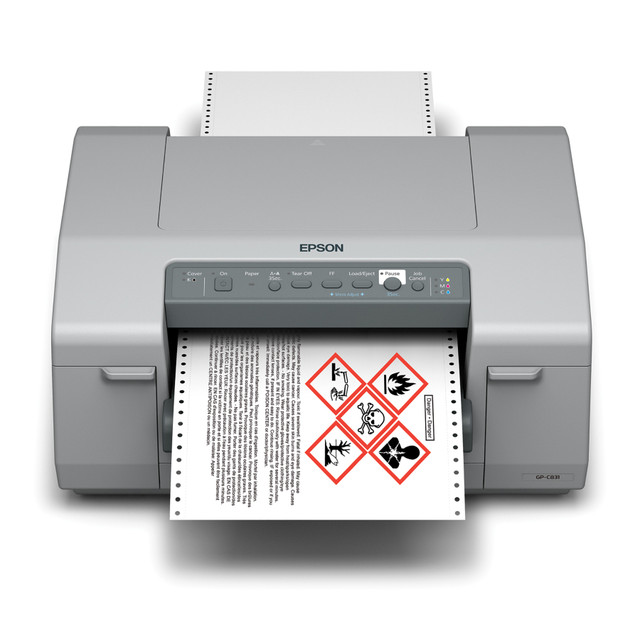

- Chemical-Resistant Labels: For under-the-hood applications, options like the GP-C831 5.75″ x 8.875″ Chemical Labels offer compliance-grade durability.

These materials ensure labels remain legible for months, even under exposure to UV rays, oils, or moisture.

Streamlining Workflow in the Shop

Implementing oil change labels effectively requires more than good materials — it needs process alignment.

Integrate with Your POS or CRM

Connecting your printer to customer management software lets technicians auto-populate label data directly from the job order, reducing input time and preventing errors.

Keep Labels Accessible

Place printers and label rolls at each bay or technician station to eliminate bottlenecks. A small thermal printer like the TSC TTP-225 fits comfortably in tight spaces and requires minimal training.

Standardize Label Templates

Consistent design across all locations reinforces your brand and improves technician efficiency. Whether using color-coded categories (e.g., full synthetic vs. conventional oil) or icons for tire rotations, visual consistency enhances readability.

Train Staff for Accuracy

Technicians should know which data fields are essential and how to verify them before printing. A short training session can prevent misprints and wasted rolls.

Boosting Customer Retention with Smart Labeling

The best service centers don’t just fix vehicles — they build relationships. Oil change labels can become a subtle but powerful retention tool.

Consider including:

- QR Codes that link to online appointment scheduling.

- Promotions like “10% off your next service.”

- Seasonal reminders for tire changes or inspections.

When designed thoughtfully, these additions encourage repeat visits and boost engagement without extra marketing spend.

It’s also wise to maintain consistency between physical and digital communication. A label that matches the same color palette and tone as your service emails reinforces brand cohesion across all touchpoints.

Sustainability and Waste Reduction

Modern label manufacturing is becoming more environmentally responsible. Many buy thermal transfer printers now support linerless label rolls, reducing paper waste. Others use eco-friendly adhesives and recyclable materials without sacrificing performance.

By switching to sustainable label media, service centers can reduce environmental impact while maintaining professional standards — a win for both branding and responsible business practices.

How Oil Change Labels Improve Efficiency

Let’s summarize how effective labeling transforms auto shop operations:

| Area | Impact |

| Customer Communication | Clear service details boost trust and encourage timely returns. |

| Technician Productivity | Digital integration reduces manual entry and errors. |

| Brand Consistency | Professional designs reflect reliability and attention to detail. |

| Compliance & Recordkeeping | Labels double as maintenance records for customer files. |

| Marketing & Retention | Branded reminders and promotions drive repeat business. |

In short, labeling doesn’t just organize information — it creates value at every stage of the customer journey.

Common Labeling Mistakes to Avoid

Even a good labeling system can fall short if improperly implemented. Watch out for these pitfalls:

- Using Non-Durable Labels: Paper or low-grade adhesives can peel or fade quickly.

- Ignoring Adhesive Compatibility: Not all adhesives stick equally well to glass or plastic.

- Overcrowding Label Text: Keep designs simple for legibility.

- Skipping Quality Checks: Periodically review printed labels for clarity and alignment.

- Not Updating Templates: Outdated logos or contact information hurt credibility.

Addressing these details ensures every label looks sharp, professional, and effective.

Small Labels, Big Impact

Oil change labels may be small, but their impact on efficiency and customer experience is massive. They bridge the gap between technician and driver, turning a simple sticker into a communication, branding, and retention tool.

From customizable rolls like the Oil Change 2.0″ x 2.0″ Labels, to rugged chemical-resistant options like the TSC TTP-225 Oil Change Kit, DuraFast Label Company offers a complete range to meet every automotive need.

Investing in professional-grade labeling isn’t just about aesthetics — it’s about precision, consistency, and building long-term trust. To explore options for oil change labels and buy thermal label printers online, visit DuraFast Label’s solutions page. For personalized guidance or integration support, contact them to speak with an expert who can guide you toward the perfect setup.

About the Author

Daniel Rees is a logistics technology writer who covers labeling systems, warehouse automation, and operational efficiency. He helps readers understand how the right print technologies can streamline business processes and improve accuracy.