Metal fabrication is one of the cornerstones of modern industry. From the cars we drive to the buildings we work in, fabricated components are everywhere. These parts may seem simple at first glance, but behind every bracket, beam, or enclosure lies a process that demands accuracy, reliability, and efficiency.

Today, industries such as automotive, aerospace, construction, warehousing, and energy rely on precision fabrication to maintain safety, reduce costs, and achieve performance standards. In this post, we’ll explore the main processes behind metal fabrication, why precision is so critical, and what businesses should consider when choosing a fabrication partner.

What Is Metal Fabrication?

Metal fabrication refers to the processes used to cut, shape, and assemble raw metals into finished components. Unlike mass-casting methods, fabrication usually involves sheet metal or metal profiles that are cut, pressed, bent, or welded into specific forms.

Some common examples include:

- Structural supports for buildings and warehouses

- Enclosures for machinery and electronics

- Automotive parts such as chassis elements or exhaust systems

- Aerospace components where both strength and weight matter

- Everyday products like furniture frames or shop fittings

What makes fabrication unique is its flexibility. Engineers can take a concept — even a one-off prototype — and turn it into a physical product using a combination of different manufacturing techniques.

Key Processes in Modern Fabrication

Over the years, fabrication has evolved from manual cutting and welding to highly automated, computer-controlled systems. Today’s workshops often use several integrated processes, each with its own benefits.

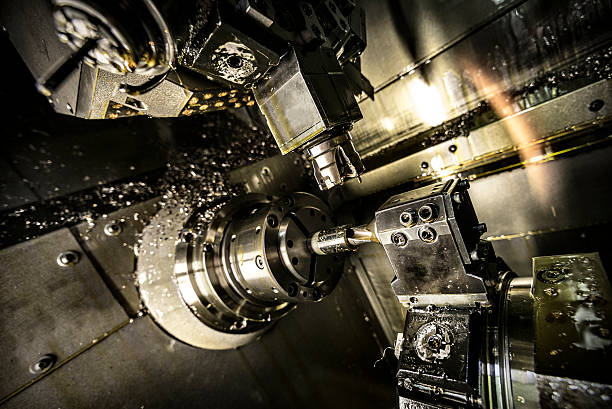

CNC Machining

CNC (Computer Numerical Control) machining uses computer-guided equipment to cut and shape metals with extremely high accuracy. By programming the exact dimensions into a 3-axis or 4-axis CNC milling machine, parts can be produced with tolerances as tight as ±0.01 mm.

CNC machining is ideal for both prototype development and high-volume production, as it offers repeatability without sacrificing accuracy.

Laser Cutting

Laser cutting has become one of the most popular methods for profiling sheet metal. A CNC fiber laser cutting machine can cut through materials such as mild steel, stainless steel, and aluminium with incredible precision.

The advantages include:

- Minimal material waste thanks to precise nesting

- Clean edges that often require no finishing

- The ability to produce complex or artistic designs

- Fast turnaround for both prototype and production orders

Many businesses now rely on professional laser cutting services to supply custom sheet metal components quickly and accurately.

Welding

No fabrication project is complete without welding. Joining processes such as MIG welding, TIG welding, and arc welding create strong, reliable connections between components.

- MIG welding is fast and suited to thicker materials.

- TIG welding provides a cleaner, more precise finish, ideal for stainless steel and aluminium.

- Arc welding is robust and effective for heavy-duty repairs or structural applications.

The choice of welding process depends on the materials, design requirements, and intended application.

Presswork

Metal presswork is the process of stamping or forming sheet metal into a desired shape using presses and custom tools. It’s an efficient way to produce repeatable components at scale.

There are different forms of presswork, such as:

- Deep drawn presswork, which creates seamless, hollow shapes like housings or containers

- Steel presswork for heavy-duty structural elements

- Custom precision metal stamping for small, intricate parts

Because it can handle both short runs and high-volume production, presswork remains a vital process in manufacturing.

Why Precision Matters

In fabrication, even the smallest error can have major consequences. Consider these examples:

- In construction, a poorly fabricated beam can affect the stability of an entire building.

- In aerospace, minor tolerance errors can lead to performance failures or safety risks.

- In automotive manufacturing, inaccurate pressings can delay assembly lines and increase costs.

Beyond safety and functionality, precision also impacts cost-efficiency. Accurate cutting, stamping, and machining reduce material waste, improve turnaround times, and lower the risk of costly rework.

That’s why many businesses today place a strong emphasis on working with suppliers who have ISO-aligned quality systems and proven experience in precision fabrication.

Choosing the Right Fabrication Partner

With so many options available, how do businesses select the right partner for their fabrication needs? A few key factors to consider include:

- Range of Services – A provider offering CNC machining, laser cutting, welding, and presswork under one roof can simplify production and reduce delays.

- Material Capabilities – Look for suppliers who work with stainless steel, aluminium, mild steel, and other metals relevant to your project.

- Production Flexibility – Whether you need a prototype, a small batch, or a long production run, the right partner should adapt to your requirements.

- Quality Standards – Certifications and ISO-aligned systems show that quality is built into every stage of production.

- Engineering Support – Development support for design and prototyping can save time and money during the early stages of a project.

For businesses seeking long-term solutions, working with an experienced partner ensures not just reliable parts, but also efficient collaboration and technical support.

The Future of Metal Fabrication

As industries continue to evolve, fabrication is becoming more advanced. The use of automation, robotics, and digital design software is streamlining workflows, while sustainable practices are reducing material waste and energy use.

Technologies such as 5-axis machining and 3D laser cutting services are expanding what’s possible in terms of design complexity and production speed. Meanwhile, increased demand for lightweight yet durable materials is pushing innovation in aluminium fabrication and stainless steel processing.

Businesses that stay ahead by adopting these modern techniques will gain a competitive edge, particularly in sectors where precision and efficiency are non-negotiable.

Final Thoughts

Metal fabrication is more than just cutting and welding — it’s a sophisticated process that supports industries worldwide. By understanding the core techniques and recognising the importance of precision, businesses can make better decisions when sourcing their components.

Whether you need CNC machining, welding, presswork, or professional laser cutting services, choosing the right partner ensures your projects are delivered on time, on budget, and to the highest standards.