There’s something deeply satisfying about watching a plain T-shirt or hoodie transform into a show-stopping piece of wearable art. Whether you’re a designer, small business owner, or hobbyist, using heat press adhesives might just be your secret to that premium, polished finish customers love. This process doesn’t just decorate fabric—it elevates it.

The Power of Transformation in Fabric Design

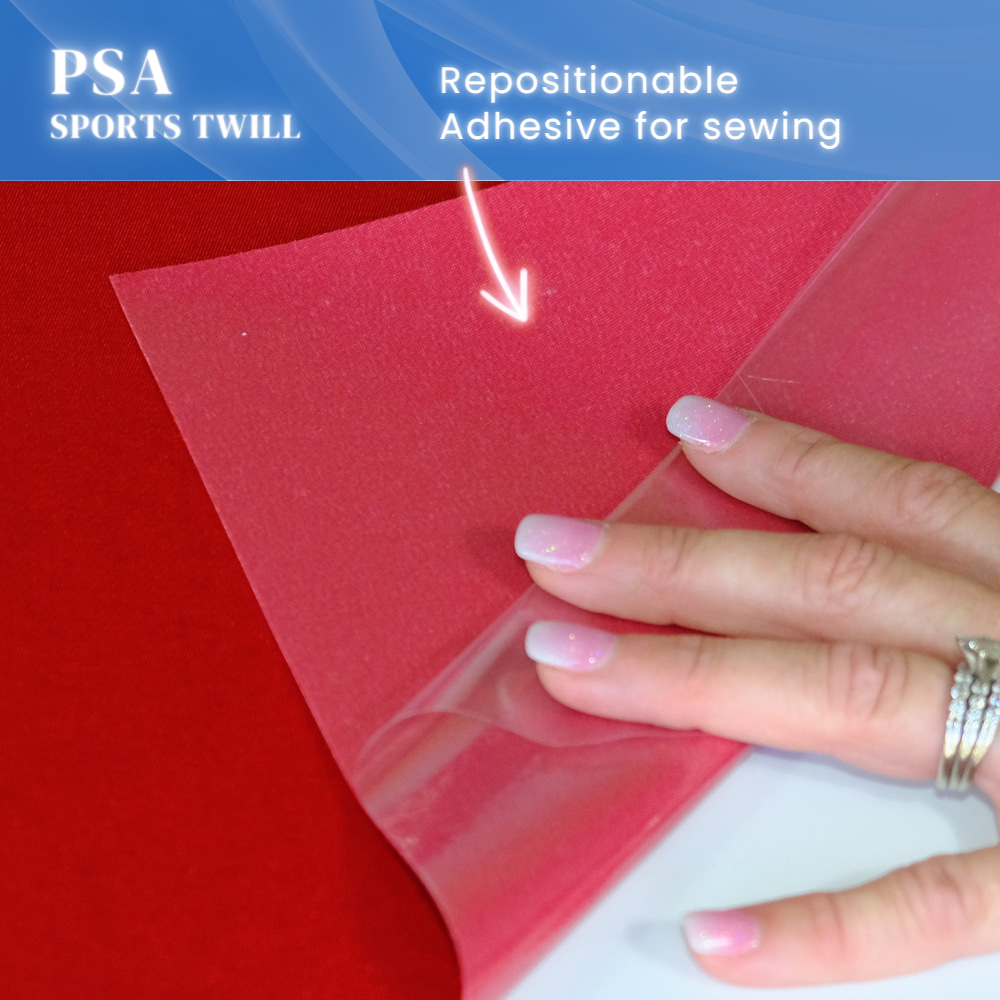

Clothing design has evolved beyond simple prints and stitching. People today look for garments that feel custom-made, unique, and expressive. That’s where heat press adhesives step in. These versatile materials help you bond appliqués, lettering, and patterns directly onto fabric surfaces, giving them a crisp, elevated appearance that’s durable and visually stunning.

Unlike traditional sewing, which may limit design freedom, adhesive application allows smoother curves, precise edges, and creative layering. It’s a tool that makes every project faster, neater, and more professional-looking.

Why Every Designer Should Explore Heat Press Techniques?

If you’ve ever tried cutting and stitching fabrics for detailed designs, you know how time-consuming that process can be. Heat press adhesives simplify it remarkably. You can bond almost any fabric layer quickly using heat and pressure, saving hours of manual work.

More importantly, the finished result often looks cleaner and feels smoother on the fabric. You could call it the best of both worlds: craftsmanship meets convenience. Whether you’re creating team logos, school emblems, or fashion patches, these adhesives give you more control over your creative outcomes.

The Secret Behind That Professional Finish

Professional-looking designs often have a few shared characteristics—smooth application, precision in alignment, and long-lasting durability. The secret ingredient that makes all that possible? It’s usually heat press adhesives.

When activated under a press, the adhesive melts and forms a uniform bond with the base fabric. This ensures that every edge adheres perfectly without bubbling or lifting. The result feels soft yet sturdy, blending seamlessly with the fabric rather than sitting stiffly on top.

Another underrated benefit is consistency. Once you perfect your heat settings and timing, you’ll achieve identical results across hundreds of pieces. That level of reliability is hard to match through stitching or gluing by hand.

Creative Possibilities That Inspire

Designers love experimenting with colors, textures, and layers. Heat press adhesives open endless doors for creativity. You might combine glossy vinyl with matte twill, or layer fabrics for a dimensional look that catches the light.

These adhesives also allow you to work with an exciting range of materials: cotton, polyester, fleece, and blends all respond beautifully to heat pressing. You’re not restricted to just flat surfaces—try unique placements or mix textures to give your apparel a boutique-style appeal.

What makes it even more fun? You don’t need an industrial setup to get started. With a reliable press, you can produce studio-quality pieces right from your workspace.

Durability That Matches the Look

The beauty of customization is meaningless if the design fades or peels after a few washes. That’s why heat press adhesives are valued for their durability. Once bonded correctly, they can withstand multiple wash cycles, everyday wear, and even stretching—without losing their charm.

This reliability builds trust among your customers and allows you to offer garments that truly last. You’re not just making fashion; you’re creating quality.

Efficiency That Saves Time and Effort

For anyone managing high production runs or small batches, time efficiency matters. Heat press adhesives cut down preparation and finishing time significantly. There’s no need for excess trimming, no loose threads to manage, and no risk of stitch errors.

The process is straightforward: cut your design, align it on the garment, apply heat and pressure, and peel. Within seconds, you have a professionally finished piece ready to impress. The reduced labor effort also means you can focus more on creativity and design refinement.

Aesthetic Appeal That Speaks Volumes

Visual appeal is everything in apparel decoration. Whether it’s bold logos or intricate appliqués, heat press adhesives give your work that elevated, boutique-level finish. They make colors pop, edges sharper, and textures richer.

Beyond just looks, the smooth surface and soft touch add to the perceived value of the garment. Your customers might not know exactly what makes the piece feel “premium,” but they’ll sense the difference immediately.

The Sustainable Edge

Modern makers are increasingly conscious about waste and sustainability. Using heat press adhesives can help reduce material wastage since there’s minimal trimming and no thread use. Many adhesives are also designed to work efficiently at lower temperatures, which saves energy and extends the life of fabrics.

For businesses, this approach aligns with eco-friendly production goals while maintaining design excellence. It’s a practical, planet-conscious choice that doesn’t compromise quality.

Conclusion

Transforming basic apparel into something extraordinary doesn’t require a complete overhaul of your process. Sometimes, it’s about the smart materials you use—and heat press adhesives are one of those quiet game-changers.

They make your creations more durable, professional, and visually captivating. Whether you’re designing for fashion, sportswear, or casual collections, this method gives you the power to turn ordinary pieces into something truly special.

For even more stunning results, try combining heat press adhesives with twills fabric to achieve a layered, textured finish that feels as good as it looks. That’s how simple garments turn into premium masterpieces worth showing off.

How Many Sessions of Laser Acne Scar Treatment Are Needed?

How Long Does Fractional Laser Recovery Take

Corteiz Windbreaker – Lightweight Urban Street Jackets

Immigration Lawyers Toronto: Expert Legal Guidance for Your Canadian Immigration Journey

Moving from Sunshine Coast to Brisbane: A Complete Relocation Guide