Book production and finishing have changed rapidly in recent years. Publishers, print houses, and packaging businesses now face higher expectations for quality, speed, and customization. Readers notice details more than ever, and book edges are no longer just functional—they are part of the visual identity. Traditional methods struggle to keep up with these demands due to limited flexibility and slower turnaround times. This is where digital innovation makes a clear difference. Upgrading to modern edge printing technology helps businesses stay competitive, reduce manual effort, and deliver consistent results. A smart investment today can improve productivity, open new design possibilities, and support long-term growth in a fast-moving print market.

Understanding the Value of a Book Edge Digital Printing Machine

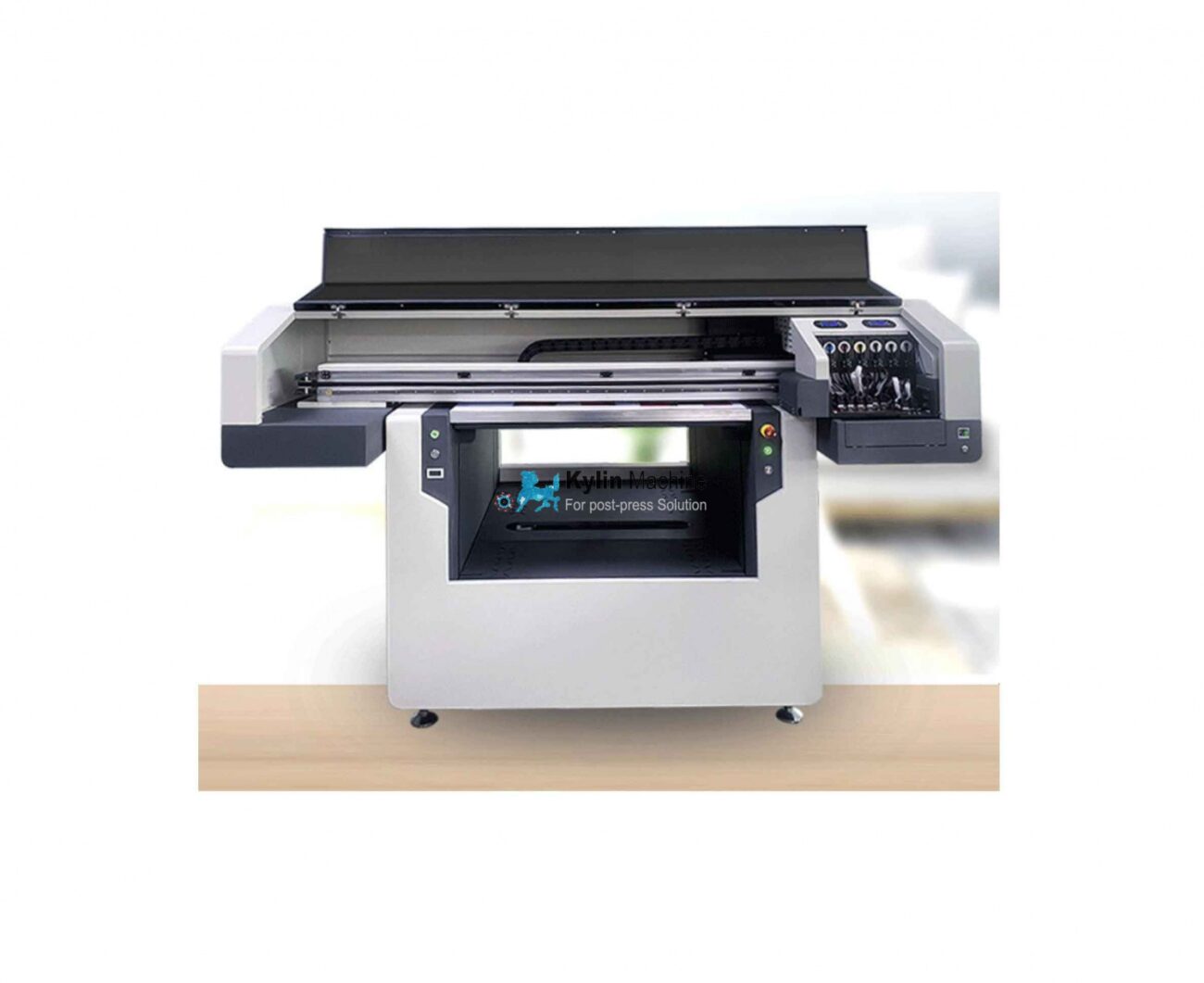

A Book Edge Digital Printing Machine is designed to print directly on the edges of books with high precision and consistency. Unlike older techniques that rely on manual processes or basic equipment, digital machines use advanced print heads and software control.

This technology allows sharp graphics, smooth color transitions, and repeatable results across large volumes. Whether producing limited editions or high-volume runs, digital edge printing ensures uniform quality. Businesses gain better control over designs and can easily switch between patterns without changing physical plates or tools.

Another key advantage is accuracy. Digital systems reduce misalignment and ink waste, which helps maintain professional standards while lowering operational costs over time.

How a Book Edge Digital Printing Machine Improves Print Quality

Print quality is one of the strongest reasons to upgrade. A Book Edge Digital Printing Machine delivers clean, vibrant edges that enhance the overall appearance of books.

High-Resolution Output

Digital printing supports detailed designs and fine text on book edges. This level of clarity is difficult to achieve with traditional methods.

Consistent Results

Every copy looks the same, from the first book to the last. This consistency builds brand trust and improves customer satisfaction.

Color Accuracy

Advanced color management systems ensure that printed edges match design expectations, even for complex or multi-color artwork.

Why Speed and Efficiency Matter in Modern Printing

Time is a critical factor in today’s printing industry. Faster turnaround often decides whether a project is profitable.

Reduced Setup Time

Digital machines require minimal setup. Designs are uploaded digitally, eliminating the need for manual adjustments or plates.

Faster Production Cycles

Automated processes allow more books to be completed in less time, helping meet tight deadlines without compromising quality.

Lower Labor Dependency

With automation handling complex tasks, fewer manual steps are required. This reduces human error and improves workflow efficiency.

Cost Benefits of Switching to Digital Edge Printing

Upgrading equipment may seem expensive at first, but long-term savings often outweigh the initial investment.

Less Material Waste

Precise ink application reduces excess usage, cutting down on wasted materials.

Lower Maintenance Costs

Modern digital machines are built for durability and require less frequent servicing compared to older systems.

Scalable Investment

As demand grows, digital machines can handle higher volumes without significant additional costs.

Customization and Creative Freedom for Publishers

Customization has become a strong selling point in publishing and packaging.

Unique Design Options

Digital edge printing supports gradients, images, and patterns that make books stand out on shelves.

Short-Run Flexibility

Small batches or special editions can be produced without increasing costs significantly.

Easy Design Changes

Digital files can be edited quickly, allowing rapid updates based on market trends or client requests.

Supporting Sustainable Printing Practices

Sustainability is no longer optional in the printing industry.

Reduced Chemical Use

Digital printing often uses fewer harsh chemicals compared to traditional methods.

Energy Efficiency

Modern machines are designed to consume less power while delivering higher output.

Environment-Friendly Operations

Lower waste and efficient ink usage contribute to greener production processes.

Staying Competitive in a Changing Market

Market competition is increasing, and customers expect innovation.

Meeting Customer Expectations

High-quality printed edges add perceived value, helping businesses attract premium clients.

Expanding Service Offerings

Edge printing opens new revenue streams, including decorative, branded, or themed book designs.

Future-Ready Technology

Digital machines are adaptable to new software updates and design trends, ensuring long-term relevance.

Key Factors to Consider Before Upgrading

Before investing, several factors should be evaluated carefully.

Production Volume

Choose a machine that matches current and future output needs.

Compatibility

Ensure the system integrates smoothly with existing workflows and software.

Training and Support

Reliable technical support and training are essential for smooth operation.

Why Now Is the Right Time to Upgrade

Technology adoption is often about timing. Delaying upgrades can lead to lost opportunities.

Rising demand for visually appealing books, faster delivery expectations, and increasing competition make digital edge printing a strategic move today. Early adoption allows businesses to refine processes, build expertise, and stand out in the market before the technology becomes standard.

Robotjet-global: Advanced Solutions for Digital Edge Printing

Robotjet-global provides innovative printing solutions designed to meet modern industry demands. The company focuses on precision, reliability, and performance, offering advanced machines that support high-quality book edge printing. With a strong emphasis on automation and digital control, Robotjet-global helps businesses improve efficiency, reduce waste, and achieve consistent results. The solutions are built to support creative freedom while maintaining industrial-level productivity. By combining technology with practical design, Robotjet-global stands as a dependable partner for printers looking to upgrade and stay competitive in a fast-evolving market.